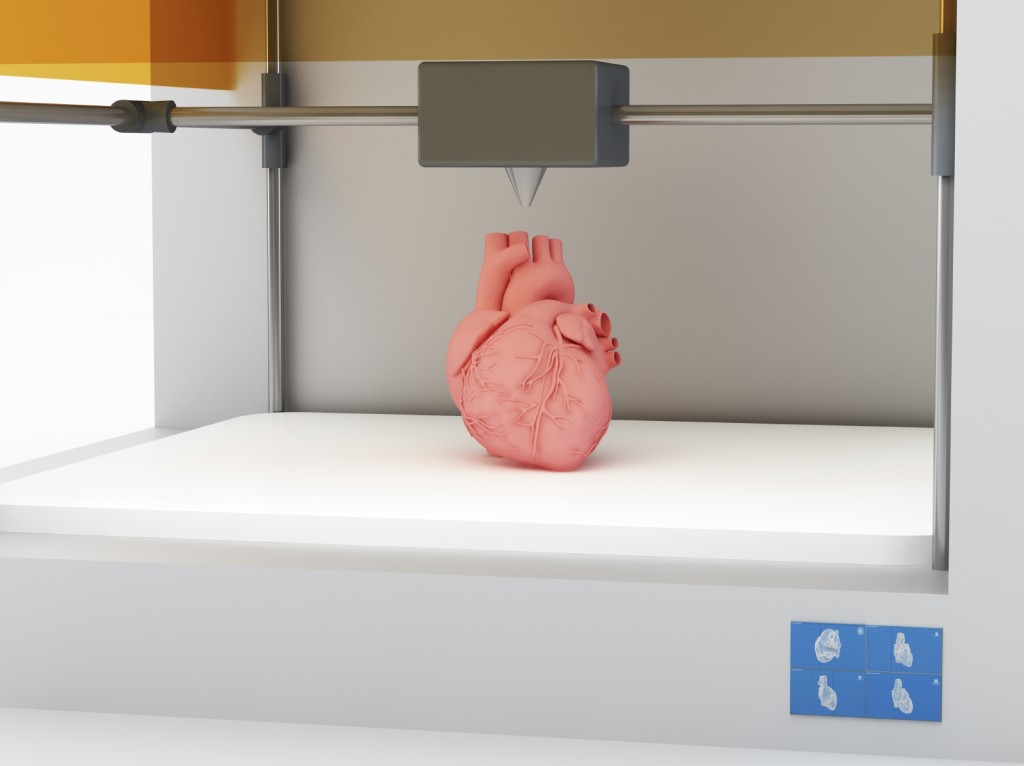

3-D Printing Body Parts

3-D printing has developed at an astounding rate in the last few years; the ability to 3-D print nearly everything brought solutions to problems in a variety of industries, like mechanical engineering and space exploration. And it seems like medicine is also greatly benefiting from this technology, mainly the field of tissue engineering.

Researchers can now print living tissue structures to replace injured or diseased tissue. Their custom-designed printer was able to create structures that were placed in animals, and they succeeded in maintaining those structures alive.

How is it Possible?

The technology, called Tissue and Organ Printing System (ITOP), creates a water-based gel that, once solidified, gains the consistency of living tissue. It also allows blood vessels to be accommodated in that tissue, so they can receive oxygen and nutrients; cells can then be added to the structure. The materials used are bio-degradable and don’t harm the cells.

There is one issue researchers need to overcome, however. Any tissue thicker than 0.2 millimetres doesn’t allow the cells to receive enough oxygen and nutrients, which leads to the necrosis of that tissue.

But, that said, the printed tissue already has a vast array of applications, since it can vary in terms of strength – for example, the gel can solidify into the consistency of muscles, cartilage and bones, and researchers hope that this will lead to the printing of other human tissues.

Why This Matters

The implications for the field of medicine are extremely important. Since living tissue structures can now be printed to replace injured or diseased tissue, ITOP has the potential to bioprint tissue and cartilage for people with missing body parts, meaning reconstructions with bioprinted organs could be widely available in the future.

And the shortage of donated organs could be solved by simply having them custom-made for each patient – or, at least, the waiting lists for organ transplant could be greatly reduced. To have a body part that perfectly fits, the scientists involved in the project need to use imaging techniques and allow for the transferring of that data to their software, which could then be printed to flawlessly match the patient.

Here at European Springs Ireland, we’re interested in the advancements made in the engineering industry every day, like in 3-D printing, and we pride ourselves of offering top quality products that help move it forward – this is why we’re compression spring manufacturers as well as providers of information on these recent developments.

If you want to know more about what we do, don’t hesitate to contact us or call us on 028 9083 8605. Alternatively, you can also follow us on Facebook, Twitter and Google+.