A Closer Look at Our Gas Springs

Our gas spring range is unique and renowned for the diversity that we can produce. Our standard collection of gas springs comprises of over 900 different items that can be combined with approximately 100 end fittings and accessories.

We design and create a complete selection of springs that can be used for various applications, across virtually every industry, from aerospace to marine application.

This blog will look at exactly what a gas spring is and how we design these powerful mechanisms.

What is a Gas Spring?

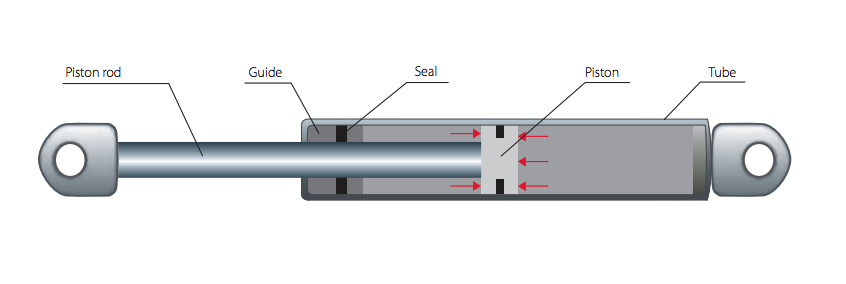

A gas spring is usually made up of a cylindrical body filled with nitrogen gas, a piston rod, a seal and a guiding function that allows the mechanism to extend and compress as required.

In contrast to most other spring types, gas springs have a built-in pre-tension force and a flat spring characteristic. This means that there is only a small difference in force between full extension and full compression.

The pushing force is powered as the nitrogen gas exerts pressure on the piston from inside the cylinder. The exact force is set by the dimensions of the spring and the specific internal pressure.

Due to gas springs’ versatility, they are regularly used for car hatches and hoods or other adjustable applications, including tables, chairs, ventilation openings, and hospital beds.

Types of Gas Spring

Gas springs are incredibly varied in form, and here at European Springs and Pressings, our standard range adds up to over 770 different products.

We’re proud to stock the highest quality conventional, lockable, standard and bespoke springs. If you can’t find what you’re looking for, we can design and manufacture bespoke items.

If you already know the type of gas spring you need, then take a look through our spring catalogue (PDF). From page 152, you’ll find a range of sizes, force and diameters.

Gas Spring Applications

The unique spring and dampening characteristics of our gas springs mean that they can be used for several applications.

One of the most common uses is lifting and unloading or controlled opening and closing of doors and hoods. Springs can also be installed to control parts of equipment, such as beds, windows, tools and machinery. Heavy items can also be lifted by hand with the help of a gas spring.

We have plenty of experience in choosing the right gas spring for various requirements. If you need a specific force or alterations to any other elements, we offer many custom variants, including adjusting the length and force, movement and dampening, connectors, as well as the tube colour and finish.

Design and Technology

We regularly train our experienced team, who are not only designers but also act as problem solvers, ensuring we reach quality for every design. Whether your application requires a standard gas spring or a custom gas spring, we can help you find the best solution.

We’ve been designing gas springs for over 70 years, and so we believe our range is exceptionally varied and technologically advanced. Our skilled design team can determine a suitable gas spring to solve any problem, even if you haven’t decided upon the exact specifications.

We have a proven history when it comes to problem-solving. So regardless of whether you need an almost conventional spring with slightly adjusted capabilities, a lockable gas spring, or a unique product, we’re able to cater to the needs of virtually any project.

Using a software package that has been developed in-house, we can simulate any type of application, which enables us to quickly calculate the force required for your particular design.

If you’d like more information about our range of gas springs, please contact European Springs Ireland with your enquiry. Our experienced team will be happy to answer your questions.