The applications of springs are vast, spanning healthcare, manufacturing, and the automotive industry, where they serve a wide range of essential functions. They are even found in spacecraft systems, including satellites and robotics, playing a crucial role in advanced mechanisms.

In this blog, we will explore the diverse applications of springs and pressings in space exploration, highlighting their vital role in ensuring precision, reliability, and control in extreme environments. At European Springs Ireland, we tailor our products to meet the demands of various sectors, including the aerospace industry, guaranteeing longevity and exceptional performance in every component.

The Challenges of Springs in Space

It’s unsurprising that there are several challenges for the components that make it to outer space, as they’re exposed to a different set of environmental conditions. There are several considerations and obstacles that springs in space have to overcome; here are just a few examples:

- Gravity: In space, springs are required to function reliably without gravity, meaning that they have to be constructed to work based on force application rather than reacting to gravity as they do on Earth. Springs can experience reduced extension and compression due to the lack of gravitational force and can expand or contract more freely, which can impact the overall spring’s performance. Moreover, the spring constant, a key factor in determining the stiffness of a spring can also experience changes in space. This is due to a lack of gravitational force, meaning that the spring’s weight doesn’t contribute to the force exerted, so the spring constant may need adjusting to reach desired levels of force when in space.

- Temperature: In space, springs are subject to drastically different temperatures than on Earth, in both extremely cold and hot variations. Springs, therefore, need to be constructed with these considerations in mind to ensure reliable performance in outer space. Special coatings and certain spring materials adapted to these conditions can be utilised by spring manufacturers for this application.

- Degradation: There are certain environmental factors that can lead to spring degradation whilst operating in space, such as cosmic and solar radiation. Degradation overtime from these environmental conditions leads to changes in the spring’s mechanical properties. They can become more brittle or experience a reduction in elasticity, which influences their effectiveness.

These are just a few challenges spring designers face when crafting components to be used in this extreme environment, there are even more obstacles to overcome depending on the application.

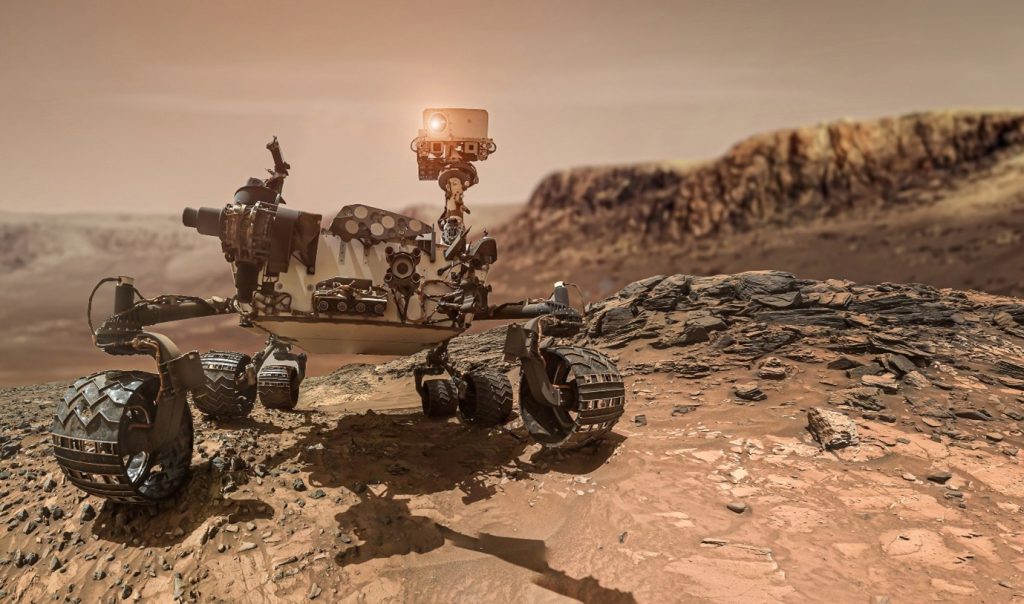

The Mars Rover: Springs on Other Planets

Springs have played an essential role in the Mars Rover missions, from the early Sojourner rover to the more recent Curiosity and Perseverance rovers, spring technology is consistently evolving to meet the extreme conditions of Mars. For instance, the Rocker-Bogie suspension system uses compression springs, maintaining stability and mobility across the rough terrain of Mars. This system was originally employed in the Sojourner rover and has been improved on in following missions.

The design and development of these springs were challenging, as manufacturers had to consider temperature fluctuations and Mars’ rugged surface. Advanced materials like memory alloys were experimented with to provide a reliable solution that could work under such demands. Springs used on these missions were tested and simulated on Earth in replicated Martian environments to check if these springs could maintain flexibility and absorb shock adequately.

The impact of these innovations goes beyond space exploration. The technologies developed for the Mars rovers are now influencing industries on Earth, such as the aerospace and automotive sectors.

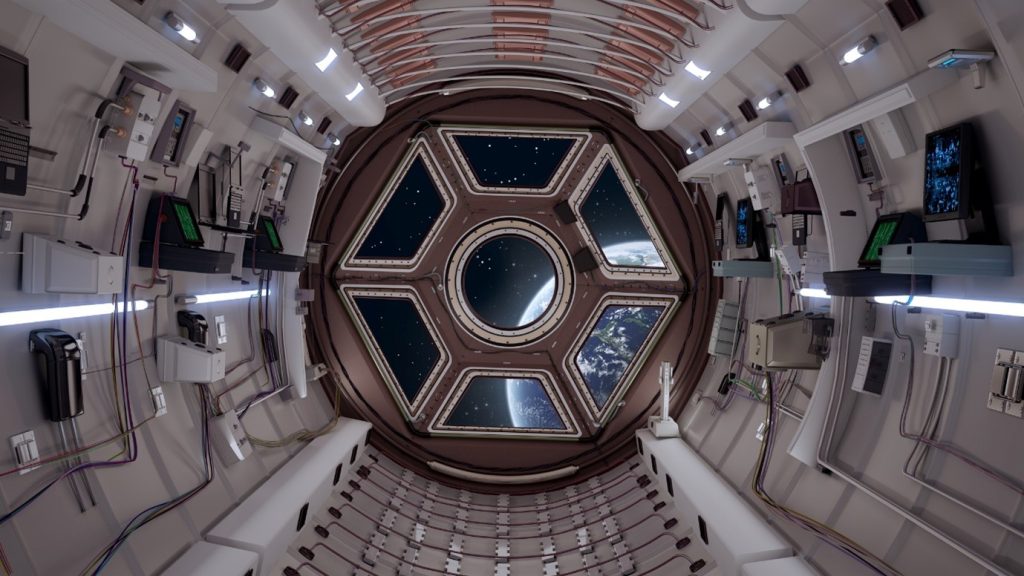

The Juno Mission: Exploring the Outer Planets

Beyond the realm of Mars, springs have also made their way to Jupiter. Launched on the 5th August of 2011 aboard the Atlas V rocket, the Juno spacecraft has travelled millions of miles to Jupiter, the largest planet in our solar system. Custom springs were used aboard this mission to perform a variety of functions, from powering the spacecraft to conducting scientific measurements.

There are over 60 custom springs aboard the Juno spacecraft, each designed to perform specific tasks. They help open the spacecraft’s solar panel doors so that the spacecraft maintains power throughout its journey. Springs also ensure the spacecraft doors remain securely latched during flying, and they assist in deploying the orbit arms once Juno reaches Jupiter, allowing the spacecraft to gather measurements of the planet’s structure.

Types of Springs Found in Space Exploration

There are several different types of springs used in space exploration; here are some of the main types:

- Compression Springs: These springs absorb and release energy when compressed. They are used in satellite deployment systems to deploy antennas and solar panels and in space rovers for shock absorption and stability on rough terrains.

- Torsion Springs: Torsion springs twist on an axis to provide rotational force. These springs are helpful in space applications where limited space is a concern, like mechanical latches or door hinges.

- Tension Springs: These springs extend under tension and are used in applications handling heavy loads over long distances. In space, they are designed to withstand extreme temperatures and potential corrosion from space conditions.

As we’ve outlined, springs play a critical role in space exploration in a number of different applications. To learn more about springs in different industries, visit our blog, and for any queries about the products we supply, please contact us.