With over seven decades of experience in our field, we have built a positive reputation both domestically and internationally as leading spring manufacturers, but what makes our services so popular? Because we work closely with our clients and take time to understand their needs and support their projects.

Finding a reliable, honest, and experienced spring manufacturer shouldn’t be a challenge, so read on to see why our processes are so successful and discover how we can support your next project.

Tailored Spring Designs for Any Application

Our customer-driven approach to spring design ensures that we meet the needs of our clients’ projects. We pride ourselves on this bespoke process that steps away from stock spring limitations and, instead, creates a product built specifically for its intended use.

This way of thinking is something we have developed not just because of our long-term expertise in this field but also because of the broad variety of sectors that we have worked with. Whether it is industrial areas such as oil and gas or commercial ventures such as machine and product design, we know that our process is highly effective at addressing a range of applications.

One proven example is the work we conducted to strengthen the well-known Öresund Bridge. Previously, severe vibrations threatened the stability of this bridge between Sweden and Denmark, and we were part of an international team designing custom dampers that featured high-quality compression springs designed to manage the problematic vibrations caused by fluctuating cables during adverse weather conditions. Our bespoke dampers, each containing precision-engineered compression springs, are designed to absorb and counteract the vibrations.

Part of the Lesjöfors Group

Another benefit our clients enjoy when choosing us as their spring manufacturers is that we are part of the Lesjöfors Group. Since 2007, we have stood alongside and collaborated with dozens of the leading manufacturers across Europe. Having access to global resources means we support and are supported in creating any springs to suit even the most demanding specifications.

This way, we continue to be the local manufacturer that our clients need, but with access to the technology, materials and designs that ensure our tailored service operates smoothly and with reliable results. It also means that we can handle projects of any size and complexity, delivering high-quality products on time and within budget.

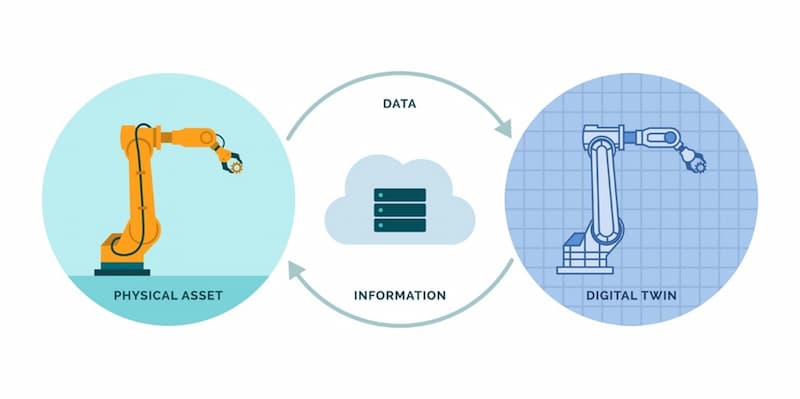

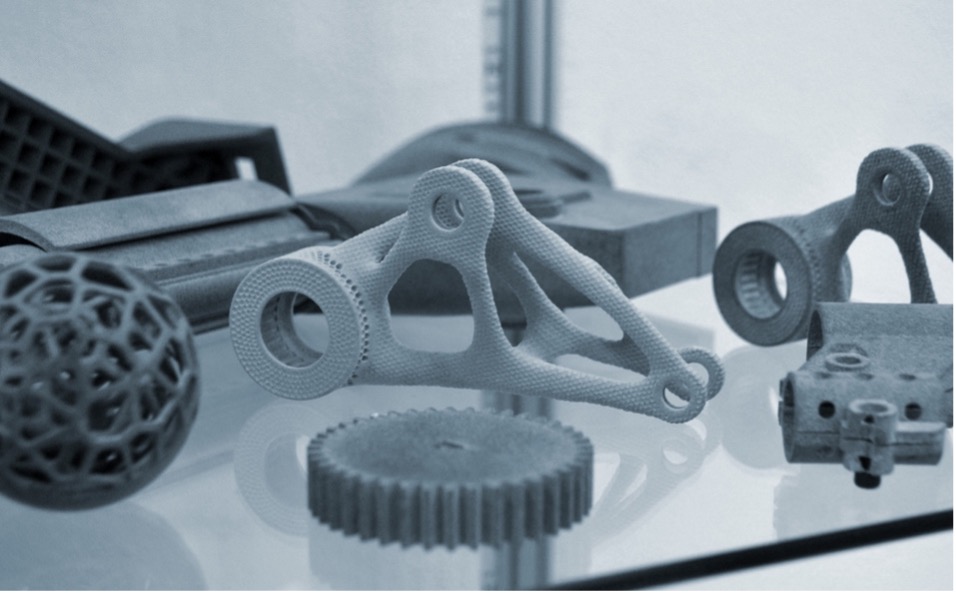

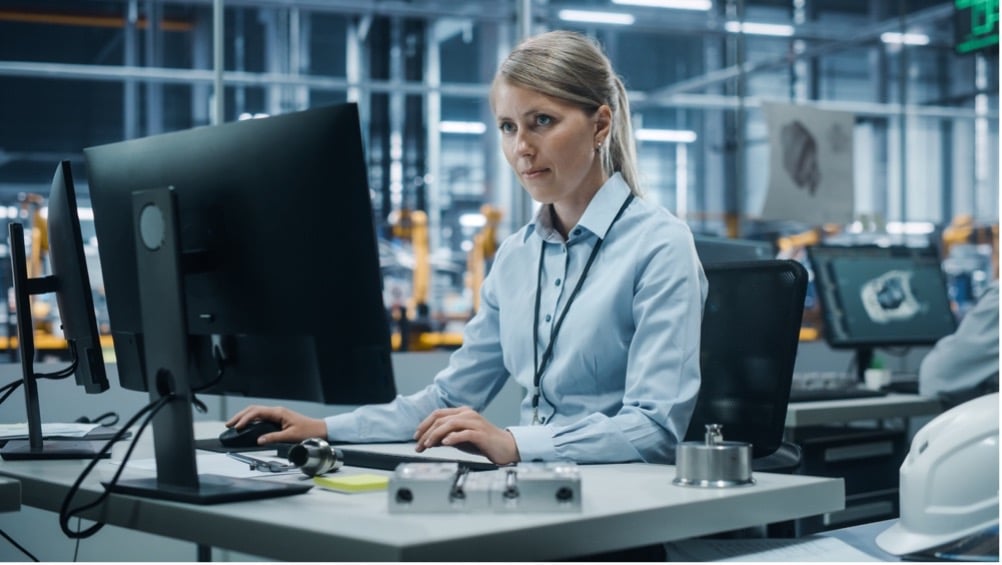

First-Class Manufacturing Facilities

We’re proud to have state-of-the-art spring manufacturing facilities that help us to serve clients across the globe. Our engineers are among the best in the industry, with years of experience and a deep understanding of spring manufacturing. We continually invest in upskilling our team and upgrading our facilities to stay ahead of industry trends and technological advancements. This commitment to innovation allows us to offer our clients cutting-edge solutions that are both efficient and cost-effective. Whether you need a custom spring design or a high-volume production run, our team has the expertise and resources to deliver exceptional results.

Commitment to Quality

Quality is at the core of all our manufacturing processes and is evident to our clients with every spring we make for them. We are fully accredited members of The Institute of Spring Technology and the Institute of Sheet Metal Engineering, which supports our registration with BSI to ISO9001 and ISO14001 standards. These certifications reflect our commitment to maintaining the highest levels of quality and sustainability in our manufacturing processes. We believe that quality begins with the materials we use, which is why we source only the best materials that meet the stringent standards required for your project.

Our in-house tooling capabilities allow us to create custom tools for each project, ensuring consistency and accuracy throughout the production process. Additionally, we offer a range of finishing techniques, such as plating, powder coating, and polishing, to enhance the durability and performance of your springs. Our commitment to quality ensures that every product we deliver is optimised for its intended application.

Sustainably Manufactured Springs

When choosing us, you are choosing a spring manufacturer dedicated to supporting sustainable manufacturing practices and regulations. The recent introduction of new carbon reporting requirements has reinforced our dedication to environmental responsibility. These regulations are designed to enhance transparency, accountability, and the reduction of carbon emissions across the manufacturing sector, aligning with the ambitious targets set by the European Green Deal to achieve climate neutrality by 2050.

Our proactive approach involved integrating energy-efficient practices into our operations, from optimising production methods to implementing waste reduction strategies. By adhering to the latest EU carbon reporting standards, we comply with regulations and contribute to a broader industry shift towards sustainable manufacturing. This dedication ensures that our clients can trust us to deliver high-quality products while also supporting global efforts to protect the environment, which can be included in their own brand as a business that values sustainability.

Leading Irish Spring Supplier

As leading spring manufacturers, we closely monitor the shifting trends within our industry. Despite the international challenges we’ve all experienced, we see a bright future for Irish manufacturing in our facility and the nation as a whole. Contact us to discuss the requirements for your next project and see how we can fulfil them.