Updated in June 2024

Constant-force springs are a particular spring type characterised by the remarkable ability to provide a steady and stable force throughout their range of motion. Thanks to this capability, they emerge as the perfect choice for uses that need a smooth return and retrieval, such as counterbalance, tensioning, and loading applications; this makes them especially valuable in the automotive and medical industries, for instance.

However, these springs are major players in another sector that has been gaining particular traction over the past few years, especially in Ireland: the space industry. Here, constant-force springs are employed to allow for the apt management of force changes within the atmosphere and in several other important applications. In this blog, we will use our expertise as spring manufacturers to delve into how the space industry relies on these springs to boost space missions and enhance key equipment.

The Key Features of Constant-Force Springs

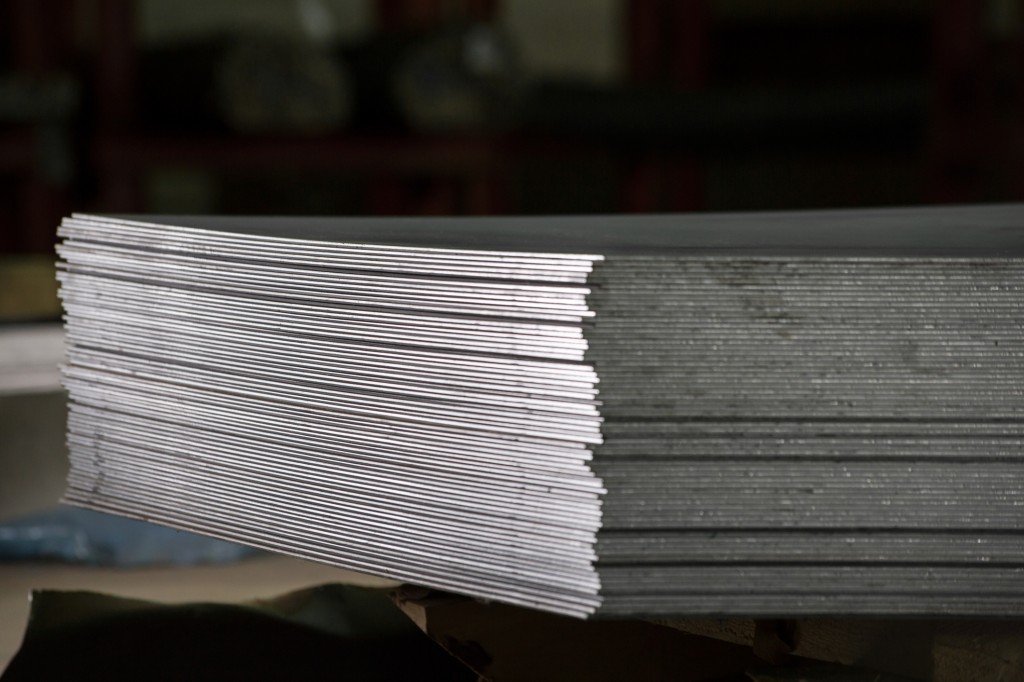

Constant-force springs boast an outstanding ability to deliver a consistent and stable force throughout their range of motion thanks to their specific design: a pre-stressed flat strip of spring material, typically stainless steel, wound tightly into a coil or on a drum. Unlike traditional springs that follow Hooke’s Law, where the force is proportional to the displacement, constant-force springs maintain their force regardless of their extension length. Because of this, they offer several advantages; let’s see the main ones.

- They deliver high force output while occupying very small space, making them ideal in compact design situations, such as in the complex spring mechanisms in aerospace engineering.

- Their long linear reach comes with minimal force build-up.

- They can store a great amount of energy indefinitely when fully extended, providing long-term performance.

The load capacity of constant-force springs can vary through different configurations, including cavity mounts, multiple spring mounts, and various sizes and designs. What’s more, their resilience and durability under harsh conditions, including extreme temperatures and vacuums encountered in space, make them suitable for the most demanding applications, like those required aboard a space shuttle.

Why Are Constant-Force Springs Used In Space?

Constant-force springs are successfully employed in the space industry because they can defy Hooke’s Law (as mentioned above) by maintaining a consistent force throughout their range of motion, which makes them particularly valuable for space applications. As they provide perpetual force regardless of extension length or speed, they are excellent in both static and dynamic applications in situations where gravitational forces differ significantly from those on Earth. Let’s delve into some of the most demanding and specific space-related employments.

Elevating Satellite Deployment Mechanisms

Satellite deployment mechanisms are one of those applications in the space sector where constant-force springs excel, as they provide the exceptional precision and reliability the operation requires. When satellites are launched into space, they are compactly stored to fit within the limited confines of the launch vehicle. To begin their mission, once they reach orbit, they need to deploy their solar panels, antennas, and other key equipment accurately. Here, constant-force springs are essential to make this deployment happen smoothly, minimising the risk of mechanical failure and improving the efficiency of satellite operations.

Additionally, spacecraft engineers know how important it is to reduce the weight and volume of onboard components, and they constantly strive to optimise payload capacity and launch costs. Satellite deployment demands high force output but in extremely limited space, so constant-force springs are the best choice to provide the necessary force without occupying significant space. This space-saving characteristic allows for the incorporation of more advanced technology in the satellite design, boosting the overall mission capabilities.

Enhancing Astronaut Equipment and Mobility

It is no secret that space is inhospitable, and astronauts require specialised equipment to perform their tasks safely, which constant-force springs enhance in terms of functionality and reliability. For instance, in spacesuits, these springs can be integrated into joints and mobility aids to facilitate smooth and controlled movements so that astronauts can move with agility, reduce fatigue, and lower the risk of injury during extended missions.

The weight of such equipment is also critical in these missions; every additional kilogram translates to higher launch costs. Whether in the tensioning systems of space tools or the retractable components of mobility aids, constant-force springs are exceptionally lightweight and efficient, making them ideal for astronaut gear.

Optimising Tensioning Systems in Spacecraft

Tensioning systems are vital for maintaining the integrity of spacecraft structures and ensuring their performance. Designed to withstand a range of harsh environmental factors, from the vacuum of space to the intense heat of re-entry, constant force springs are central to providing essential tension to hold components in place. For example, in assembling larger structures like space stations or modular spacecraft, these springs are fantastic at keeping cables and structural members securely fastened despite dynamic space conditions, guaranteeing better longevity in space missions.

Precision in Solar Panel and Antenna Positioning

Satellites and spacecraft heavily rely on solar panels and antennas, which, once positioned precisely, provide power and communication capabilities. Here, constant-force springs are employed to supply the necessary force to position these components accurately, guaranteeing that solar panels capture as much sunlight as possible to allow for energy generation and that antennas maintain optimal orientation for communication.

Let Your Space Project Take Off with European Springs IE

At European Springs & Pressings IE, we specialise in designing and manufacturing high-quality constant-force springs tailored to the unique demands of the aerospace industry. Our premium quality springs are precisely engineered to meet the most demanding requirements of space applications to achieve the utmost reliability, precision, and performance. With our bespoke approach, we offer exceptional solutions that help you achieve your mission objectives with confidence.

Whether you are developing satellite deployment mechanisms, astronaut equipment, or solar panel systems, our constant-force springs will not disappoint you. Browse our stock catalogue and contact us to learn how, as leading constant force spring manufacturers, we can help the space sector take off with innovative spring solutions that propel your projects to new heights.