In an era where everything is wireless and portable, the efficiency and reliability of battery-powered devices are critical factors to consider. The core of all these systems is the battery management system (BMS), which oversees their energy storage and release.

From establishing secure connections to withstanding harsh environmental conditions, springs are central in this process; in this blog, we will explore their role in optimising electrical performance within battery management systems. Read on to discover their applications, functionalities, and the key considerations in their design and material selection.

Battery Management Systems and Their Importance

Battery Management Systems and Their Importance

Before delving into the complexities of springs, we want to give an overview of battery management systems, commonly known as BMS. These systems stand as the gatekeepers and the overseers of the health and durability of batteries, guaranteeing their smooth, reliable, and safe functioning.

Monitored elements under a BMS’s purview range from individual cell voltages to managing the delicate balance of charging and discharging cycles. In effect, the BMS operates as the linchpin in dodging hazardous situations that can be detrimental to the life and efficiency of batteries. It nips potential overcharging and overheating situations in the bud, preventing any chances of catastrophic failures. As various industries worldwide continue to scale their demand for high-performance batteries, the part played by BMS in safeguarding these powerhouses becomes increasingly important.

How Springs Optimise Electrical Performance in BMS

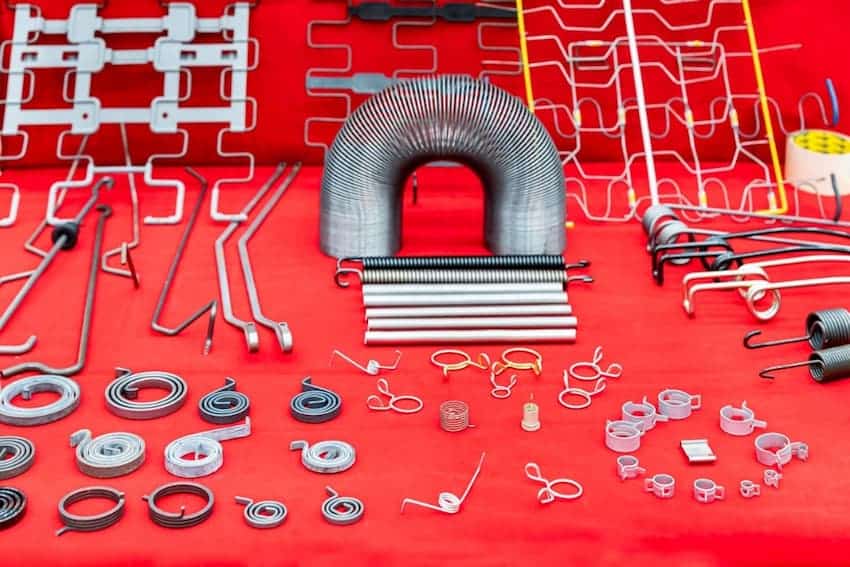

Now, let’s shift the focus towards springs, the components behind the backdrop of these advanced systems. These mechanical elements are the tiny enablers that allow all crucial aspects of the system to run smoothly, maintaining harmony within the complex matrix of the BMS.

The utility of springs within a BMS is certainly multifaceted, which highlights their indispensable nature. Being employed for a variety of tasks that collectively contribute to the system’s reliability, they essentially fortify its overall integrity. From securing electrical connections to guaranteeing uninterrupted conversations between different components to maintaining the system’s energy lifeline, springs accomplish these essential feats with great efficiency.

Applications and Functionalities of Springs within Battery Management Systems

One primary role that springs fulfil in BMS is the preservation of electrical connections. Acting as conductive elements, springs guarantee an unbroken flow of electricity between various modules and components within this sophisticated system. Whether it’s bridging the gap between individual battery cells or facilitating the interface with monitoring circuits, springs stand at the forefront of these linking processes.

Another aspect springs are involved in is the design of BMS components. They deliver the necessary tension and pressure that allows connectors to remain securely in place. Such a fixture is essential to prevent accidental disconnections, which vibrations, shocks, or thermal expansions could cause. The security offered by springs is not just handy but absolutely critical, especially for applications where precise and reliable performance is non-negotiable. A fleeting loss of connection in these contexts could have far-reaching and serious consequences.

What Influences Material and Design Choices for Battery Springs?

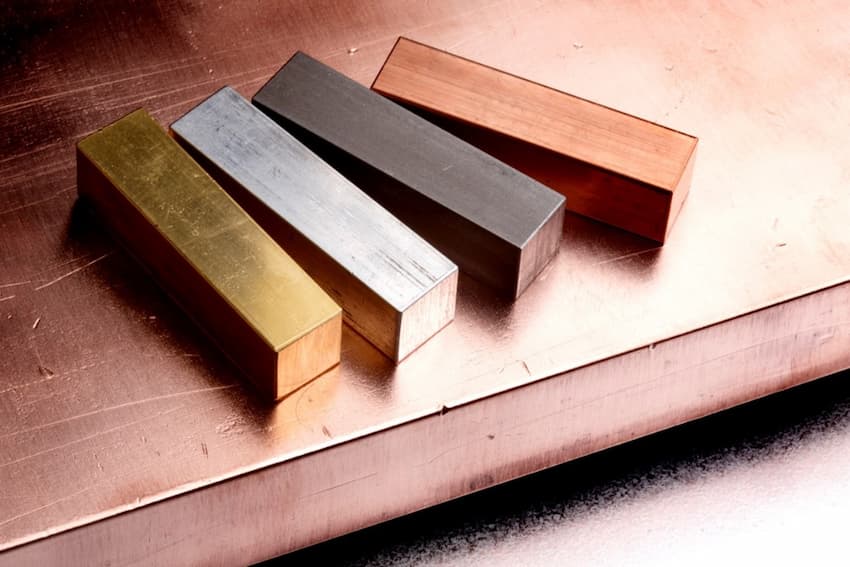

The choice of materials and designs is an articulated process, considering factors that directly impact their performance and longevity. Durability, corrosion resistance, conductivity, and designs – like compression springs or torsion springs – are necessary considerations to make. Let’s have a closer look:

- Durability: BMS often operates in challenging environments, subject to vibrations, temperature variations, and mechanical stress. Springs must be durable enough to withstand these conditions without compromising their functionality or structural integrity.

- Corrosion Resistance: exposure to various elements can lead to corrosion, negatively impacting electrical conductivity and general performance. Springs designed for battery applications must exhibit excellent corrosion resistance to maintain their functionality over an extended lifespan.

- Conductivity: the conductivity of springs directly influences the efficiency of electrical connections. Materials with high conductivity, such as certain alloys, are preferred to minimise energy loss and ensure reliable electrical performance.

Taking into account all these factors, the selection and design of battery springs become a careful balance of material science, engineering skills, and general optimisation to guarantee the most efficient performance in a multitude of operating conditions.

Selecting the Right Materials and Designs

Given their critical role in battery management systems, selecting the right materials and designs for springs is fundamental. At European Springs, as a leading springs manufacturer, we understand the specific requirements of the industry and our springs are crafted to meet the highest standards of durability, corrosion resistance, and conductivity. By employing advanced materials, including specialised alloys, we make sure our springs can be utilised in diverse applications. Also, our designs tailor our springs to provide the necessary tension and conductivity while adhering to the specific requirements of battery management systems.

The Importance of European Springs IE in Battery Management Applications

At European Springs IE, we are navigating an era of unprecedented technological evolution and have made our mark as a key player in manufacturing springs for battery management applications. As leading compression spring manufacturers, our philosophy intertwines precision engineering with a constant commitment to quality, which allows us to deliver springs that do more than meet the mark.

Our contributions towards optimising electrical performance in batteries are significant steps influencing the future of energy consumption. We trust that our efforts will continue to echo through initiatives that can help achieve a more efficient, sustainable, and reliable energy landscape. Our journey at European Springs is characterised by constant evolution, always reaching for the next peak and pursuing the highest benchmark of quality, precision, and service.

We are excited about the future; if you are ready to embrace emerging challenges with innovative solutions with us, browse our online catalogue and contact us today to change the world one spring at a time.

Battery Management Systems and Their Importance

Battery Management Systems and Their Importance

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process and serves as the building blocks of these essential components’ successful performance. In fact, their quality, strength, and overall performance are directly influenced by the materials used in their production. Whether it’s the robustness of steel springs or the corrosion resistance of stainless steel pressings, each material brings a unique set of benefits to the table.

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process and serves as the building blocks of these essential components’ successful performance. In fact, their quality, strength, and overall performance are directly influenced by the materials used in their production. Whether it’s the robustness of steel springs or the corrosion resistance of stainless steel pressings, each material brings a unique set of benefits to the table.

The Increasing High-Speed Precision Presses Demand

The Increasing High-Speed Precision Presses Demand