Mechanical engineering is an invaluable stalwart in manufacturing, driving innovation and progress through groundbreaking design, refining, and maintenance of mechanical systems. However, as industries undergo rapid technological transformations, the role of mechanical engineers in manufacturing is changing, as is their ingenuity and adaptability.

From utilising the power of automation to championing sustainable practices and driving innovation, this blog will delve into the most relevant shifts in mechanical engineering, examining the most important technological advancements, market dynamics, and societal aspects driving its evolution.

A Dive into the Evolving Technological Landscape

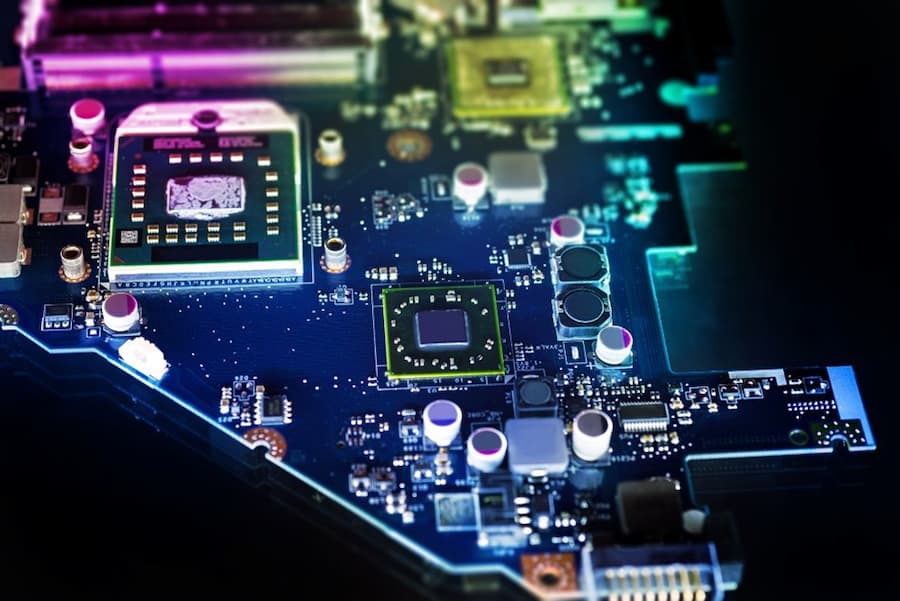

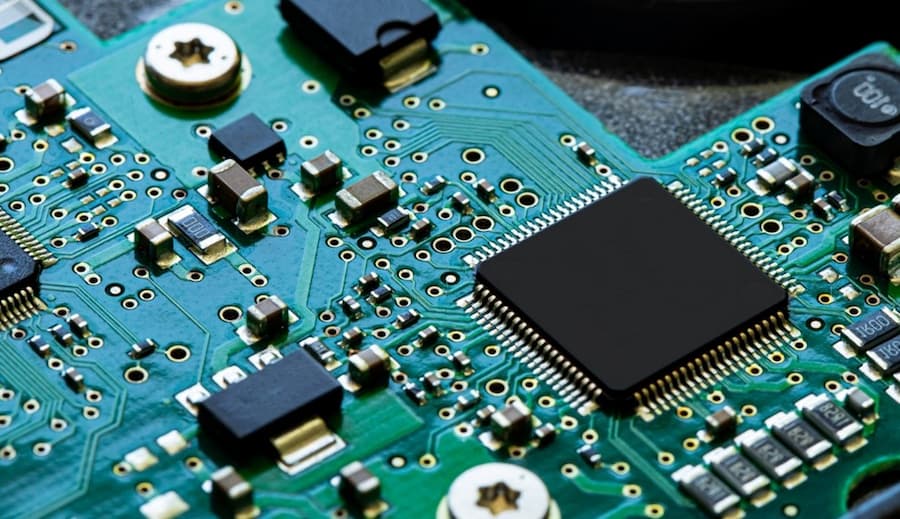

Like many other sectors, manufacturing is experiencing a technological shift propelled by rapid advancements in digitalisation, artificial intelligence (AI), and the Internet of Things (IoT). If these innovations are reshaping traditional manufacturing processes, they are also disrupting the industry by demanding a new breed of mechanical engineers equipped with interdisciplinary skills. Today’s engineers find themselves at the crossroads of hardware and software, where leveraging computational tools for design optimisation, simulation, and predictive maintenance is critical.

One prominent manufacturing example is additive manufacturing. Often referred to as 3D printing, this has also emerged as a disruptive force that facilitates and streamlines processes such as rapid prototyping, customisation, and complex geometries, which were previously more challenging to achieve. Taking full advantage of additive manufacturing and driving efficiency and agility in production would not be possible without the skills and competence of highly trained mechanical engineers, who are then tasked with navigating this complex landscape and capitalising on technology to drive both progress and competitiveness.

Modern Manufacturing: Automation and Robotics Integration

In recent years, automation and robotics have become integral parts of modern manufacturing, revolutionising production lines and upskilling human capabilities. Mechanical engineers are at the forefront of this transformation, assisting with the integration of robotic systems into existing processes. For instance, collaborative robots—or cobots, as they are called—specifically designed to work alongside workers are becoming the norm in manufacturing, improving productivity and safety in factories.

Advancements in machine vision and sensing technologies are also significantly contributing to empowering mechanical engineers to develop sophisticated robotic solutions capable of complex tasks, from precision assembly to quality inspection. However, we can’t ignore the fact that, whilst certainly helping, automation also raises some concerns when it comes to routine tasks. Engineers and designers must then adapt to such a redefining shift, embracing automation as an opportunity to focus on aspects that robots or AI can’t assist with, such as higher-value activities and creative problem-solving. Junior engineers can learn both this and how to maximise their manufacturing apprenticeships in our European Springs programs.

The Increase of Sustainable Manufacturing Practices

With growing environmental consciousness and regulatory pressures on a global scale, the adoption of sustainable practices has become one of the priorities of manufacturing. In this context, engineers have become the main drivers of this sustainability agenda, creating original solutions to minimise resource consumption, waste generation, and carbon emissions throughout the product lifecycle.

From lightweight designs to material substitution to energy-efficient systems, these brilliant minds use a genuine approach to optimise sustainability metrics without compromising performance or cost. In addition, lifecycle assessment tools allow them to quantify environmental impacts and help with informed decisions, guiding the transition towards a circular economy. As sustainability becomes synonymous with competitiveness, all this work is certainly valuable to allow the change the planet needs, spearheading initiatives that reconcile economic imperatives with environmental stewardship.

The Opportunities and Challenges of Globalisation in Manufacturing

The globalisation of manufacturing has ushered in a new era with plenty of opportunities but also challenges. Supply chains have become increasingly complex and geographically scattered, demanding a more strategic approach to efficient management. Here, aspects such as optimising supply chain logistics, leveraging data analytics to enhance visibility, mitigating risks, and streamlining processes are more critical than ever, and engineers are required to handle them cleverly.

We must also not forget how the rise of geopolitical tensions and trade disruptions constantly undermine the resilience and agility of supply chain strategies. Anticipating and quickly adapting to dynamic market conditions by employing agile manufacturing principles and flexible production systems is another challenge that mechanical engineers must solve. Collaboration across borders and cultures is then essential to promote partnerships and resilience in an increasingly over-connected world.

Driving Innovation and Product Development

Driving Innovation and Product Development

Finally, there’s innovation, driving continuous improvement and market differentiation. In this decade, where technological evolution seems hyper-fast and unstoppable, the ability to make progress swiftly and effectively is vital to maintaining a competitive edge. Interdisciplinary collaboration is key to propel innovation here, with mechanical engineers collaborating with experts from diverse fields, including materials science, electrical engineering, and data analytics.

Open innovation ecosystems certainly amplify creativity, allowing for the “cross-pollination” of ideas and speeding up the pace of revolutionary advancements. As custodians of creativity and ingenuity, engineers are agents of change in the relentless pursuit of excellence, using their technical expertise and competence to conceptualise, design, and commercialise breakthrough products and processes.

Championing Mechanical Engineers at European Springs IE

As leading spring manufacturers here at European Springs IE, we value the incredible contribution of mechanical engineers in driving innovation, which is deeply ingrained in our ethos.

We recognise and praise their indispensable input in shaping the future of manufacturing, from optimising production processes to adopting sustainable initiatives and pushing innovation. Our commitment to empowering the manufacturing sector is evident in our investment in advanced technology, interdisciplinary collaboration, and continuous learning.

By championing engineers’ expertise and creativity, we remain at the vanguard of industry progress, poised to meet our customers’ evolving needs and drive positive change in the manufacturing sector. Contact us today to learn more about our catalogue, commitment, and the industries we serve.

Driving Innovation and Product Development

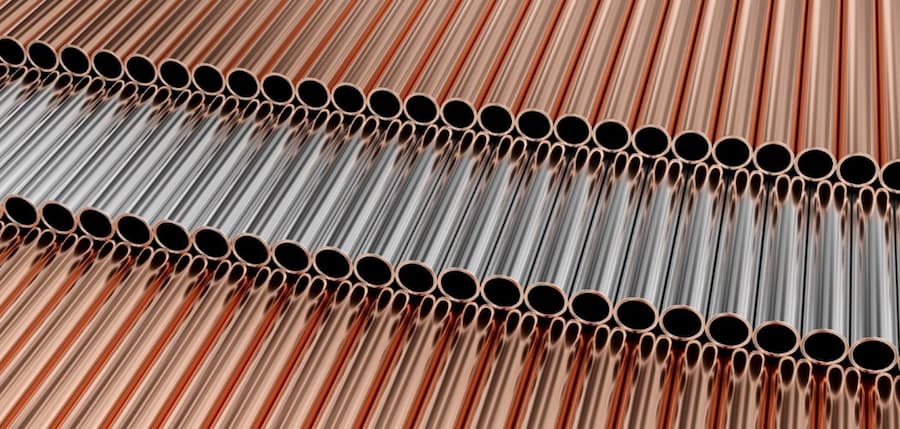

Driving Innovation and Product Development In home construction, extreme precision and overall safety are paramount and non-negotiable. In recent years, sustainability has become another key factor to consider when planning to design and build residential structures. The objective is to achieve results that not only maximise efficiency with minimal environmental impact but are also long-lasting. It is here that pressings are essential components in modern home construction, serving multifaceted roles for durability and strength.

In home construction, extreme precision and overall safety are paramount and non-negotiable. In recent years, sustainability has become another key factor to consider when planning to design and build residential structures. The objective is to achieve results that not only maximise efficiency with minimal environmental impact but are also long-lasting. It is here that pressings are essential components in modern home construction, serving multifaceted roles for durability and strength.

Since their introduction in the 19th century, the railway and public transport industries have always been on the move (literally). They have evolved at a fast pace by embracing the latest technologies to develop quickly and meet passengers’ demands responsively. In this context, springs have been indispensable in allowing such progress, contributing to the efficiency, safety, and overall experience of public transport. From ensuring the smooth movement of trains to improving the comfort of bus passengers, these components may be working behind the scenes but are essential to make trains, trams, and buses the reliable means of transportation we know today.

Since their introduction in the 19th century, the railway and public transport industries have always been on the move (literally). They have evolved at a fast pace by embracing the latest technologies to develop quickly and meet passengers’ demands responsively. In this context, springs have been indispensable in allowing such progress, contributing to the efficiency, safety, and overall experience of public transport. From ensuring the smooth movement of trains to improving the comfort of bus passengers, these components may be working behind the scenes but are essential to make trains, trams, and buses the reliable means of transportation we know today.

Why High-Quality Pressings Are Indispensable

Why High-Quality Pressings Are Indispensable

Battery Management Systems and Their Importance

Battery Management Systems and Their Importance

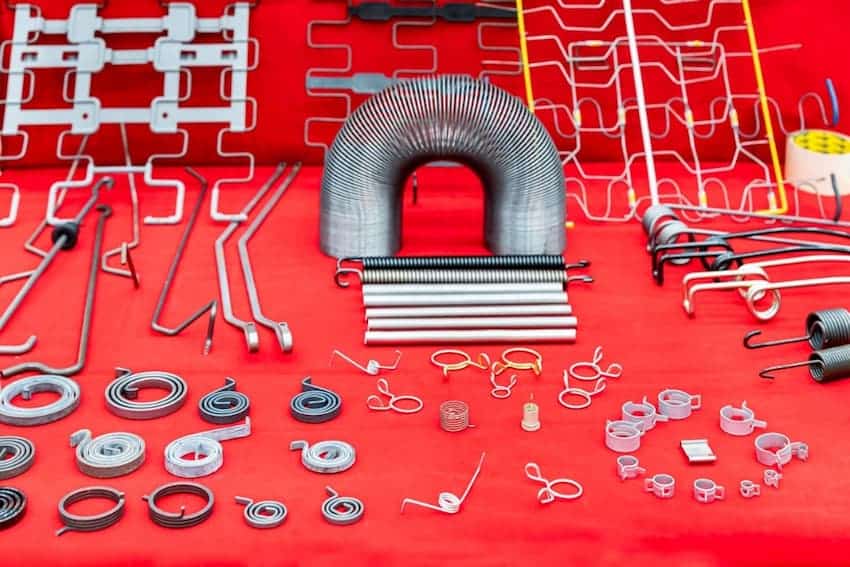

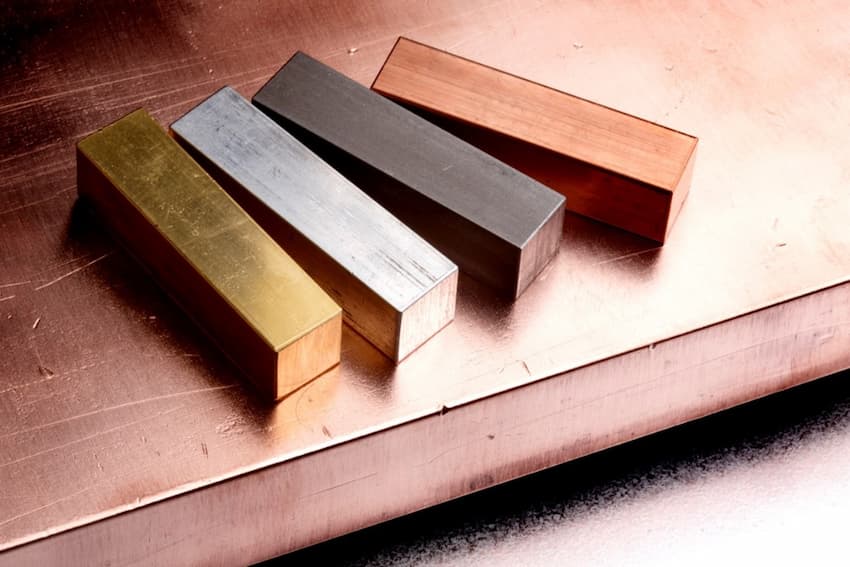

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process and serves as the building blocks of these essential components’ successful performance. In fact, their quality, strength, and overall performance are directly influenced by the materials used in their production. Whether it’s the robustness of steel springs or the corrosion resistance of stainless steel pressings, each material brings a unique set of benefits to the table.

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process and serves as the building blocks of these essential components’ successful performance. In fact, their quality, strength, and overall performance are directly influenced by the materials used in their production. Whether it’s the robustness of steel springs or the corrosion resistance of stainless steel pressings, each material brings a unique set of benefits to the table.