Reasons Why You Should Choose To Study Engineering

There will always be a demand for skilled engineers in many different fields. This is a direct result of the

Home › Engineering › Page 3

There will always be a demand for skilled engineers in many different fields. This is a direct result of the

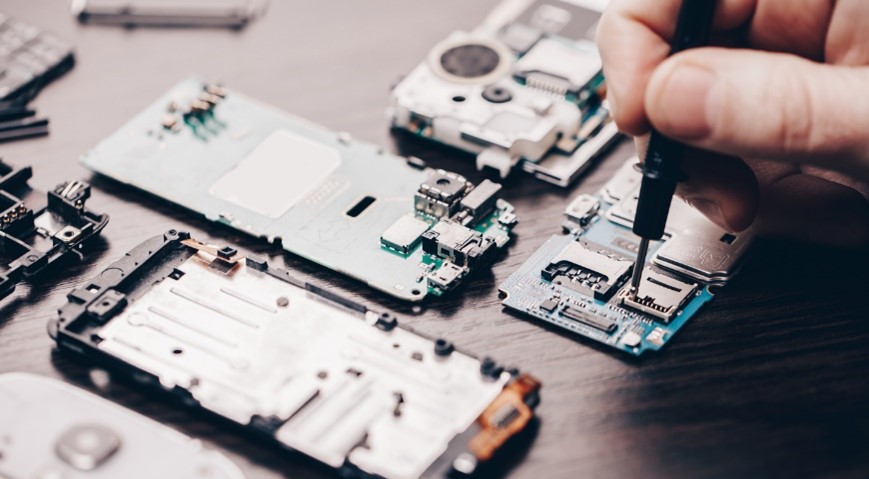

In the fast-paced world of electronics and technology, the role of wire forms cannot be overstated. These seemingly humble components

Guaranteeing that manufacturing has plenty of up-and-coming employees of the future is still one of the biggest challenges the industry

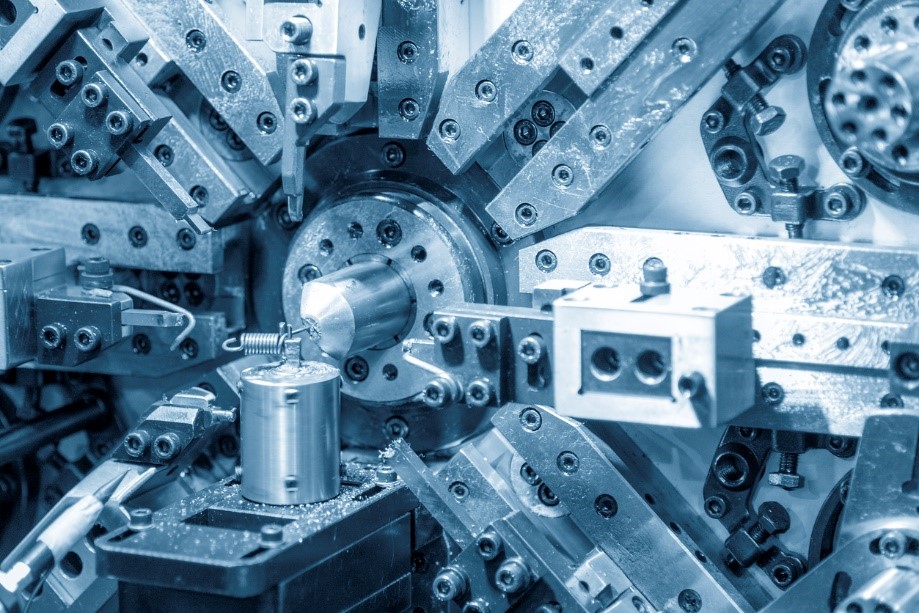

Springs are crucial in countless industries, offering essential functionality and support in diverse applications. While standard spring elements may suffice

The Irish manufacturing sector has undergone a remarkable transformation in recent years, driven by advancements in technology and digitalisation. With

There’s a lot to consider when bringing your spring and pressing designs to life, and it can be overwhelming if

As a leading provider of springs and pressings solutions, European Springs Ireland is committed to staying at the forefront of

Here at European Springs, we are leading manufacturers of springs and metal components in Ireland, and with over 70 years

The manufacturing industry has been a vital part of the global economy for centuries, and as technology continues to advance

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital