Which Industries Rely On Spring Manufacturers?

Springs are essential in many industries and play a critical role in the functions of a wide range of products,

Home › Engineering › Page 4

Springs are essential in many industries and play a critical role in the functions of a wide range of products,

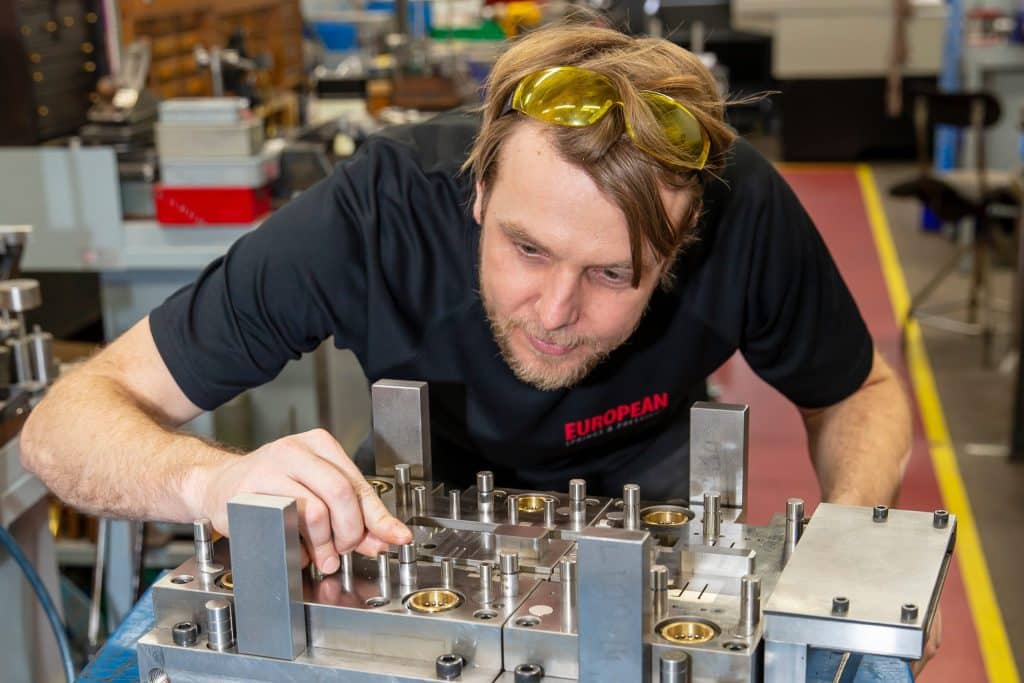

Here at European Springs Ireland, when it comes to manufacturing wireforms, we’re proud to run one of the largest production

Here at European Springs Ireland, we are dedicated to encouraging young people to join the fascinating field of spring manufacturing.

Here at European Springs Ireland, we’re committed to providing our customers with a smooth journey while working with us to

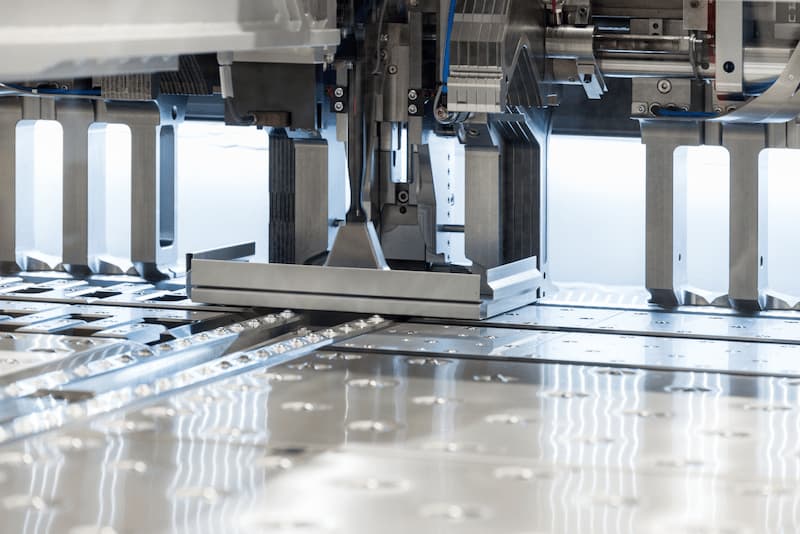

As technology creeps further into every aspect of the manufacturing industry, European Springs Ireland is excited to be at the

Deciding your future in your teen years is a daunting experience. You may feel pushed into a corner by peers,

At European Springs, we are proud of our role in manufacturing high-quality springs and pressings for a broad range of

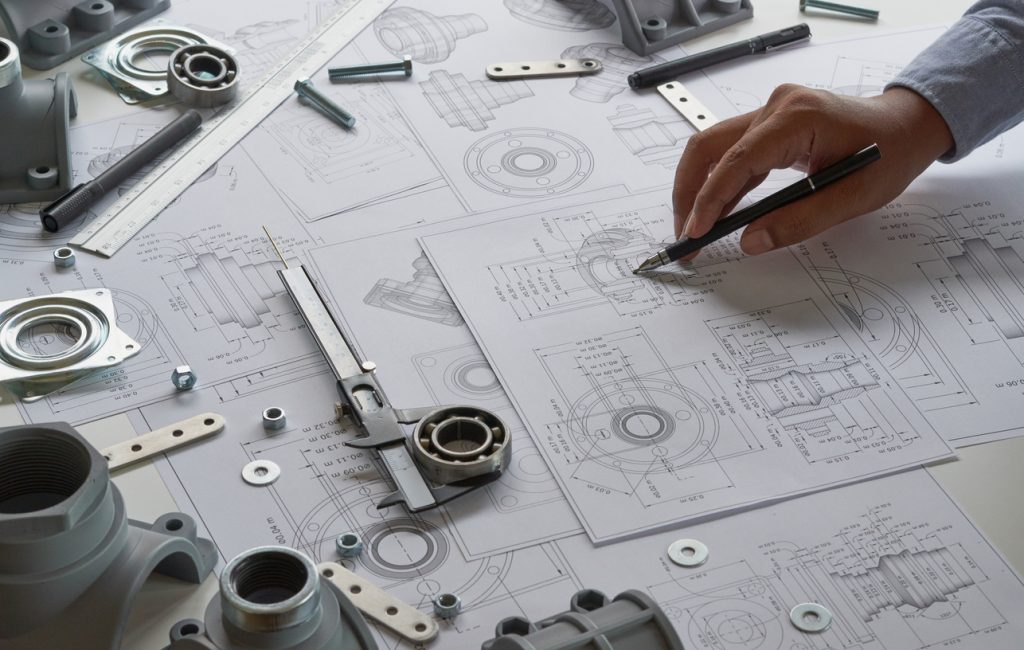

Throughout our decades of experience manufacturing high-quality pressings and stampings, we have developed our processes to create an expert service

The drive toward increased sustainability in manufacturing has never been higher as more companies within the industry join this commitment

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital