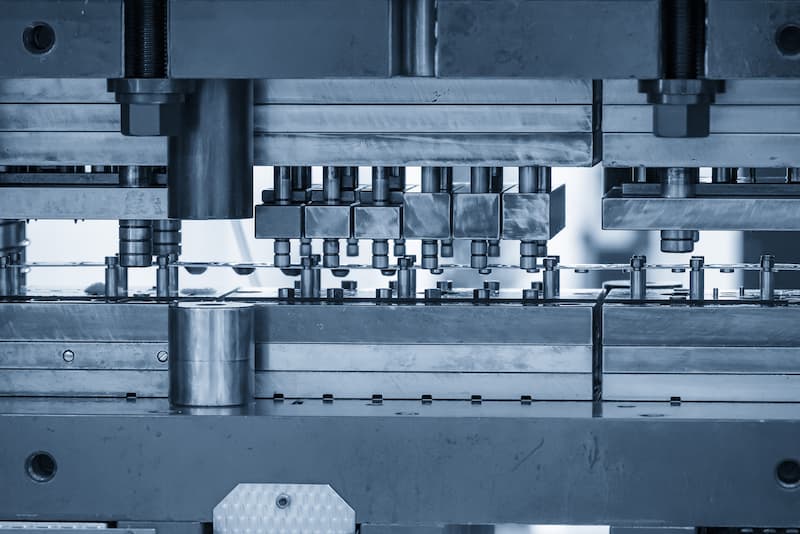

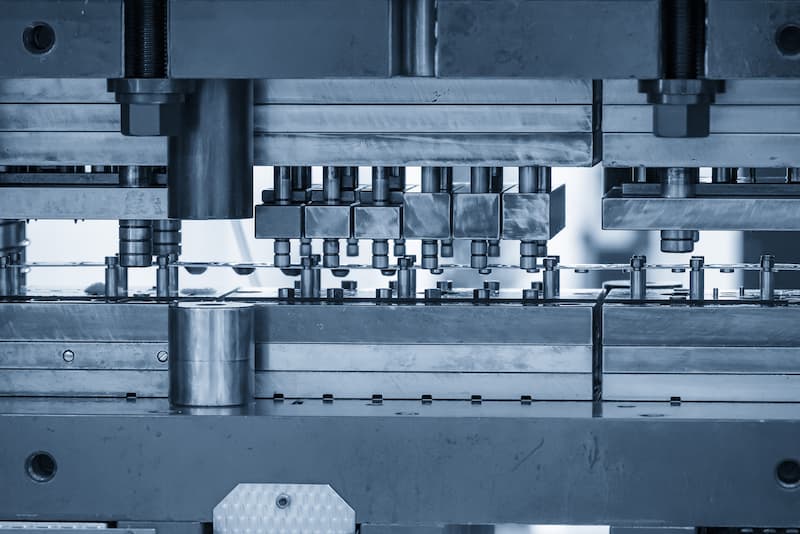

Why You Should Always Choose Bespoke Pressings

Metal is one of the most versatile materials used for manufacturing components. The ability to shape and process this durable

Home › Engineering › Page 5

Metal is one of the most versatile materials used for manufacturing components. The ability to shape and process this durable

For any company, it’s crucial to maintain a high level of productivity and look for ways to improve upon it

In recent years, the world has changed so much, and technology has risen to become the most significant driver of

There are no two ways around it; it’s been an unusual two years. Cast your mind back to 2016 when

After decades as an extreme science and engineering niche, virtual and augmented reality is now widely used as a

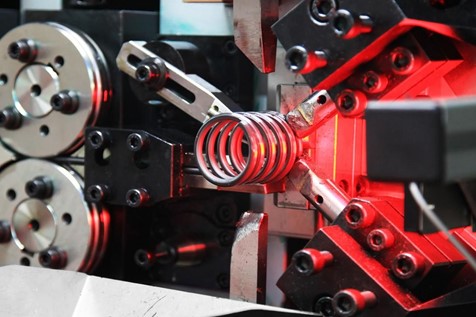

With many years of experience as spring manufacturers in the engineering industry, we’ve learnt the best way many engineering processes

Broken or failed equipment, tools, or components can significantly affect your production line and efficiency, especially if the same issue

Technology is constantly evolving, particularly in the manufacturing industry. Industry professionals and tech experts regularly find new and innovative

If you’re just getting started in the spring manufacturing industry, you may be a little overwhelmed at the number of

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital