R&D Investment For Manufacturing Required More Than Ever Before

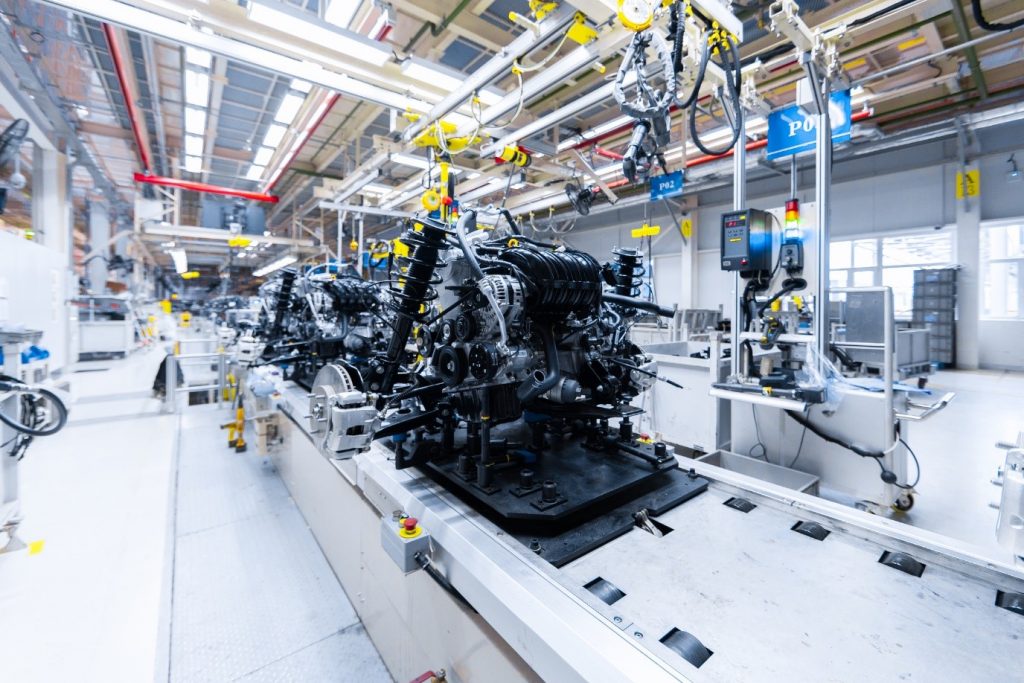

Following the peak of the UK Coronavirus pandemic many manufacturing and engineering businesses have been getting back to work over

Home › Engineering › Page 7

Following the peak of the UK Coronavirus pandemic many manufacturing and engineering businesses have been getting back to work over

As businesses around the UK do their best to adapt to the ‘new normal’, manufacturing companies are quickly finding that

With the COVID-19 lockdown still in force, the news hasn’t been the most positive, including in the manufacturing industry. However,

If your business is currently immobilised by the lockdown, you might be thinking that now would be the perfect time

Ensuring that the manufacturing industry is completely future-proofed is an essential and ongoing task that the government and leading companies

The nature of the manufacturing and engineering industry is extremely fast-paced and ever-changing. With that in mind, we thought it

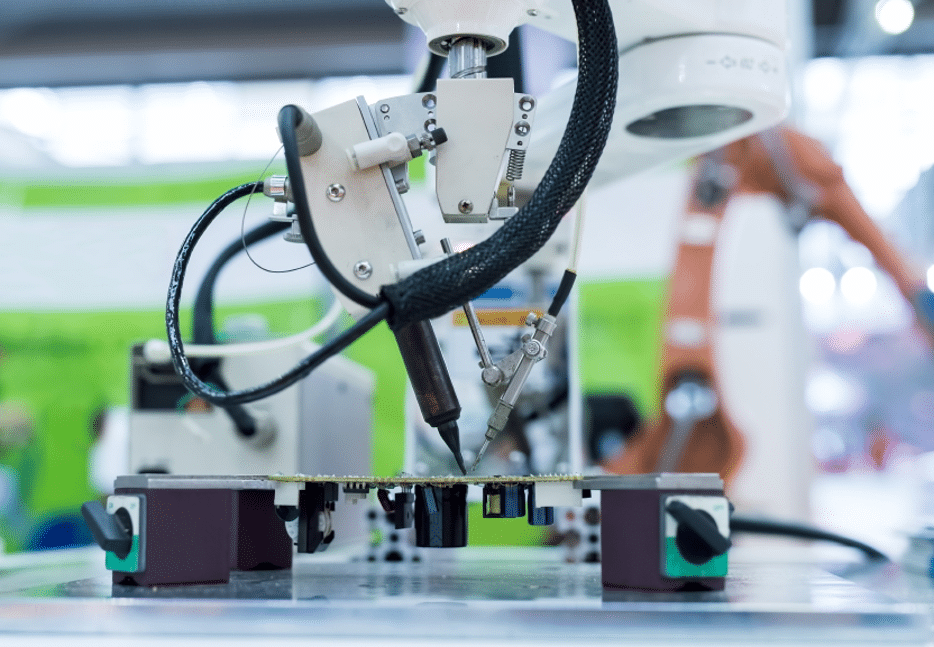

Technology continues to advance at a rapid pace and to create exciting opportunities for those working in manufacturing and its

It’s fair to say that the Internet of Things (IoT) has been revolutionising the way manufacturers work over the last

With 2020 fast approaching, there are a whole host of trends that look set to take off in the coming

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital