How To Become An Engineer

For those hopeful students starting out their engineering education, or those who are well into their studies, knowing precisely what

Home › Engineering › Page 8

For those hopeful students starting out their engineering education, or those who are well into their studies, knowing precisely what

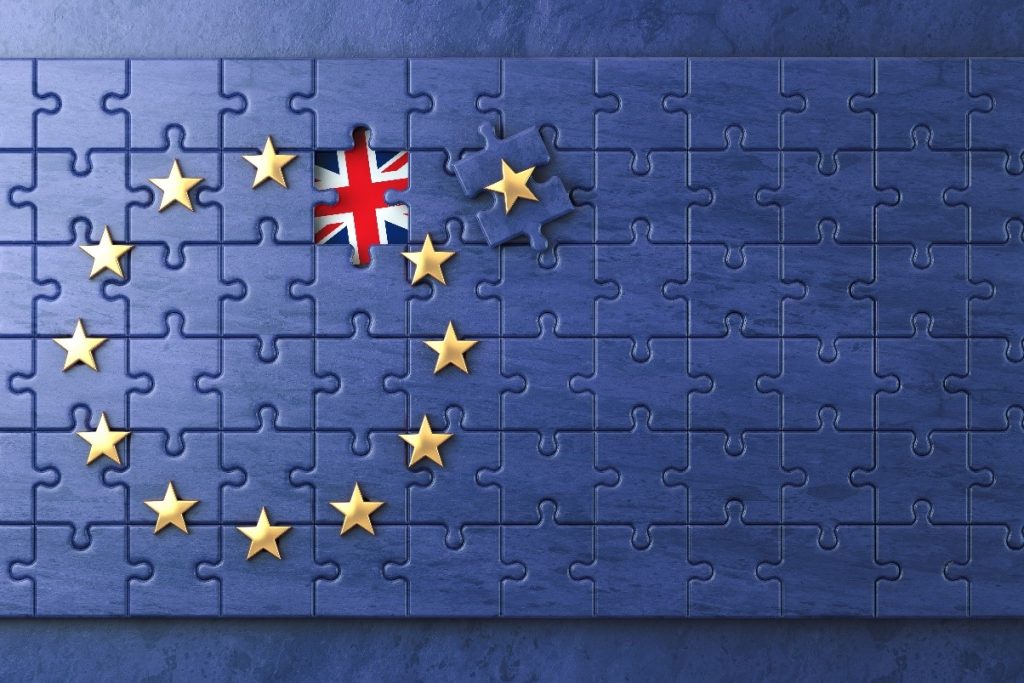

With Brexit being pushed back until 31st January 2020, manufacturing businesses have more time to ensure they are fully prepared

Manufacturing businesses across the world face a number of challenges on a day to day basis, so it’s important that

The UK has enjoyed a fantastic year in 2019; HMRC have reported that our goods exports have been breaking records

Ensuring that the next generation of engineers and scientist are given all the tools they need to succeed in their

The decline of our planet’s overall health and sustainability is a growing problem, and many businesses ask themselves whether they

In this article, we consider whether enough is being done to improve diversity in the manufacturing and engineering sectors. We

One of the latest pushes in manufacturing and engineering across the world is to develop products that are increasingly eco-friendly.

The new year is well and truly underway and those all-important resolutions you made have probably been broken and completely

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital