Springs play a crucial role in many aspects of daily life, but some of their most essential applications are in life-saving medical devices. From pacemakers to X-ray machines, springs are fundamental components that help ensure these devices function effectively. Whether compression springs, gas springs, or tension springs, their uses in life-saving technology are vast and indispensable.

As experienced spring manufacturers, we supply high-quality, reliable springs across a range of industries, from aerospace to manufacturing. We understand the critical importance of precision and durability in every spring we produce.

Read on to discover how our springs can contribute to life-saving innovations.

Considerations for Springs in Life-Saving Applications

Springs in life-saving applications must perform flawlessly. Not only to ensure the reliability of the device but also to safeguard the well-being of those who depend on it. Designing springs for the medical industry requires careful consideration of several key factors:

- Spring Material: The material that a spring is constructed from must take into account the demands of the application. For instance, some devices need to withstand exposure to harsh environments, including moisture and chemicals. This means they need to be made from a corrosion-resistant material like stainless steel.

- Spring Type: The type of spring selected is equally as important as the material, with different springs offering different benefits. For instance, compression springs are used in areas where a spring’s force is used to provide controlled movement or pressure, whereas torsion springs work best where rotational movement is required.

- Regulations and Standards: It is vital that springs comply with necessary regulations and standards. We are both ISO 9001 and ISO14001 certified, which exemplifies our commitment to quality manufacturing processes and sustainability.

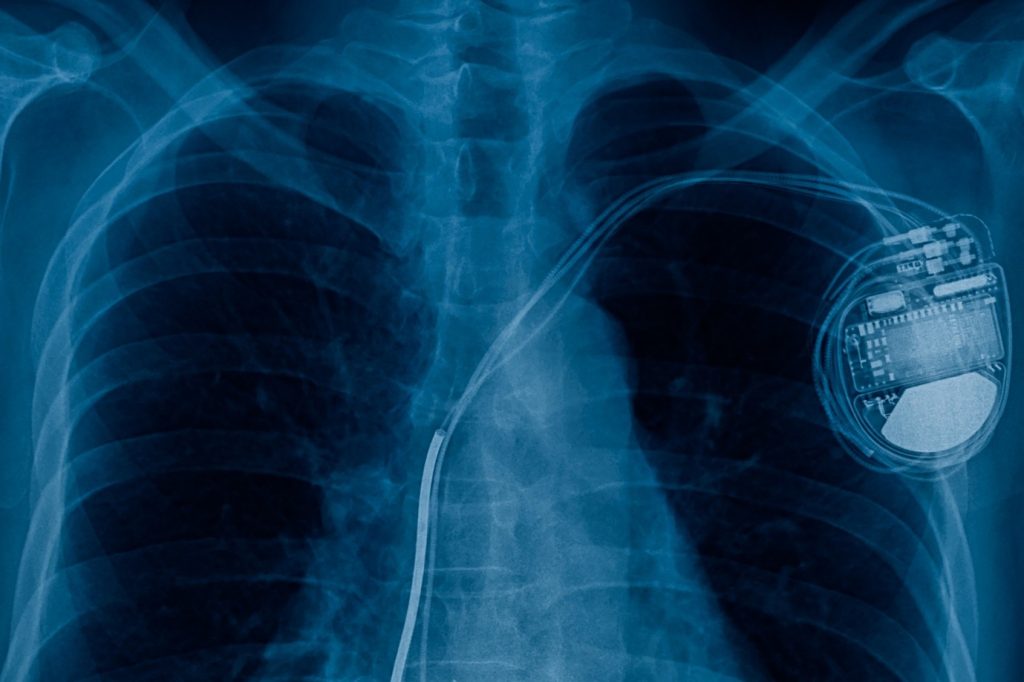

Pacemakers

The pacemaker is an important medical device that sends electrical impulses to the heart if it beats at an irregular rate, whether this is too slow, or too fast. Pacemakers are vital to the survival of many people, but did you know that springs are used to create them?

Springs are implemented in pacemakers to make sure that the leads connecting the electrical circuits to the heart do not become disconnected, otherwise known as active fixation. This is an essential component, as a dislodged or disconnected lead can lead to permanent damage to the heart. The springs found in pacemakers tend to be compression springs, a versatile and dependable form of spring that we manufacture.

Syringes

Compression springs are also commonly used in syringes, particularly in auto-injectors. These devices are designed for patients to safely and easily self-administer medication at home. The mechanism of an auto-injector is similar to that of a ballpoint pen, when not in use, the needle remains inside the syringe, and a pre-loaded spring pushes it out when the button is pressed. This ensures precise and automatic medication delivery, offering a convenient and reliable solution for patients who require injected treatments.

Ventilators

Ventilators, commonly used in hospitals, play a vital role in assisting patients with breathing. Tension springs are found in the valve mechanism of ventilators. This mechanism controls the flow of air and oxygen to and from a patient. The tension springs work to create tension which regulates the opening and closing of valves.

Compression springs are also found within ventilators, particularly in the pressure regulation system. They assist in managing the pressure of delivered air, so that it meets the set requirements of a patient’s needs. These springs need to be reliable, as they are crucial in ensuring that the pressure systems in ventilators are responsive and accurate.

Gas springs help to create flexibility in the position of certain areas of a ventilator due to their controlled and precise movement. Gas springs are found throughout hospitals, from hospital beds to adjustable wheelchairs, and are a vital tool in ensuring equipment is placed in the correct position and comfortable for both patients and healthcare workers.

Imaging Equipment

Medical imaging machines, such as X-rays, MRI, and CT scanners, are vital diagnostic tools that help healthcare professionals detect non-visible health issues. These life-saving devices rely on springs for precision, balance, and flexibility, allowing them to adjust seamlessly to patient needs.

Springs also play a crucial role in X-ray tables, enabling controlled movement for precise patient positioning. This ensures accurate imaging, which is essential for effective diagnosis and treatment.

Our Commitment to Quality and Safety

Here at European Springs, quality and safety are at the forefront of everything we do. We understand the implications of spring failure in these critical applications. That’s why we implement advanced manufacturing and quality control processes to ensure our springs are safe to be used in critical medical devices. To learn more about our processes, or to commission the production of your custom spring solution, please contact us.