One of the most common springs is the compression spring. The helical shape of this spring is probably what comes to mind when you think of springs. So, while we know that there are many applications for the compression spring, do you know what they are?

Pens

On a small scale, you are likely to find a compression spring in the pens you use every day. If they have a click top, they will contain a small compression spring which provides the tension necessary to keep the nib inside the casing when it is not in use and to push it out when the click top is pushed.

Suspension

Compression springs are often used in suspension systems as they are capable of compressing when a load is applied. This means that they are perfect for acting as shock absorbers so they are often used in cars and other vehicles to provide suspension.

Oil Rigs

You will be able to find a specific type of compression spring, the garter spring, on an oil rig. This spring is used here to ensure that underwater oil pipes keep the oil in and the water out. As they provide an inward radial force, they are able to secure a joint in the pipe.

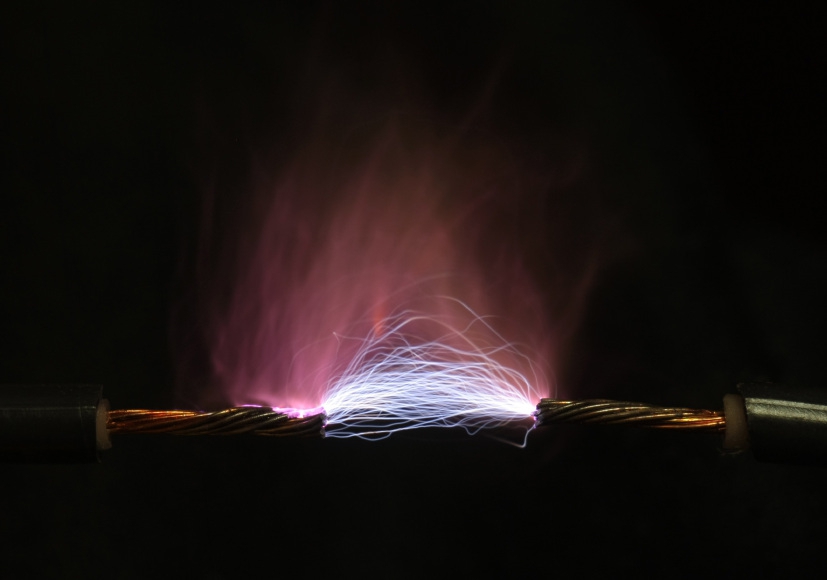

Switches

Just by looking around the room you are in, you will probably be able to spot plenty of switches. Compression springs are present within these switches as they keep the switch in the ‘on’ or ‘off’ position.

Keyboards

When you type on some computer keyboard, you are pressing the keys down onto tiny compression springs known as buckling springs. The springs allow the key to spring back up and pushes a hammer which strikes the electrical contact, telling the computer which key has been pressed.

Compression springs are used in more applications than you may think! In fact, you can probably a lot more just by looking around the room that you are in. If you are interested in finding out more about any of our products or would like to talk about your next project, please don’t hesitate to contact a member of our team who will be more than happy to advise you further. You can contact us by calling 028 9083 8605, emailing ieinfo.bec@europeansprings.com or by filling out our online contact form.

In the meantime, make sure to find us on Facebook and Twitter.

[button url=”/contact-us/” class=”scbutton”]Enquire Now[/button]