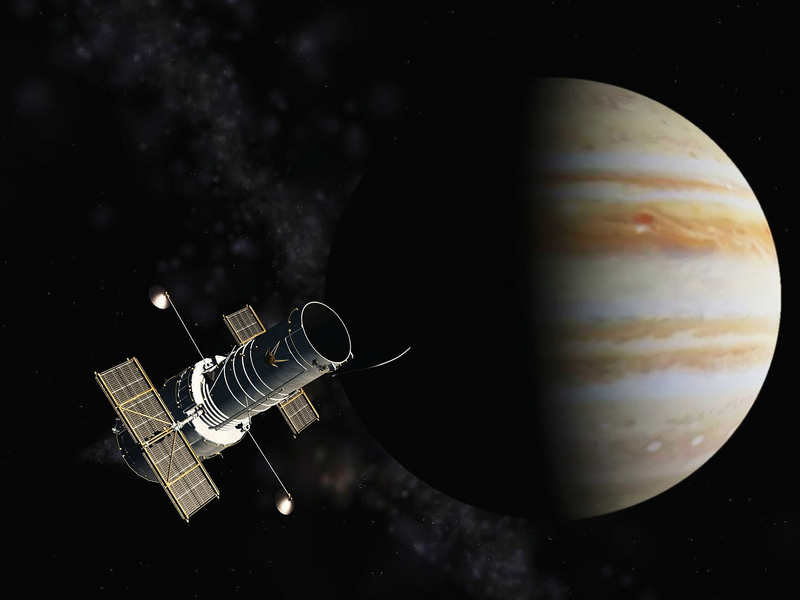

It might be the largest planet of our solar system, but since the past 5th of July we can pride ourselves on having conquered it. After a five-year-long journey – in which it has covered no less than 1.7 billion miles – the probe Juno is finally orbiting around Jupiter.

What is Juno?

This spacecraft is part of the NASA New Frontier Mission and was launched on the 5th of August, 2011, from Cape Canaveral. Unlike other spacecrafts used in missions in the outer solar system, Juno is not powered by radioisotope thermoelectric generators but solar arrays. These are more common in satellites orbiting the Earth. Nevertheless, in the case of Juno, its three solar array wings are the largest ever developed in a planetary probe and help it to stabilise and generate power.

Juno Operational Components

1. Propulsion

Juno uses hydrazine and nitrogen tetroxide for propulsion, providing a thrust of 645 newtons. The vehicle’s orientation is controlled by a monopropellant reaction control system.

2. Telecommunications

Back on Earth, scientists communicate with the spacecraft using a 230ft antenna that utilises an X band direct link. This system is also being used by Juno to send photographs from Jupiter – such as the beautiful ones in which we can see the planet dancing with its four moons.

3. Solar Panels

Juno has only three, symmetrically arranged. Two of them have four hinged segments, and the third one has three segments and a magnetometer. Each panel is 8.9ft by 29ft long, which makes them the largest ones ever used by NASA on a deep-space probe.

Juno’s Travel

1. August 2011

Juno was launched from Earth and placed in a heliocentric orbit.

2. October 2013

After travelling for two years, Juno passed by the Earth again, using the planet’s gravity to propel itself – this manoeuvre has been called a ‘gravitational slingshot’. The spacecraft received a boost in speed of more than 8,800 miles per hour before heading towards Jupiter. But before that, scientists in Earth took advantage of this fly-by and tested some instruments and procedures with Juno.

3. July 2016

When Juno reached Jupiter’s orbit, its trajectory changed from hyperbolic to elliptical. Thanks to this, the spacecraft will be closer to Jupiter than any other machine of its kind before. Besides, it minimises the contact with Jupiter’s dense radiation belts that, potentially, can damage the spacecraft and its solar panels.

4. October 2016

Juno will be orbiting around Jupiter gathering as much information as it can about the planet and its surroundings.

5. February 2018

It is scheduled to disintegrate into Jupiter’s atmosphere. When this happens, it will burn out and disappear very quickly. This has been done so the spacecraft doesn’t collide with any of Jupiter’s moons by accident. This will also reduce the risk of space debris and contamination according with NASA’s Planetary Protection Guidelines.

What Mysteries Will Juno Be Able to Explain?

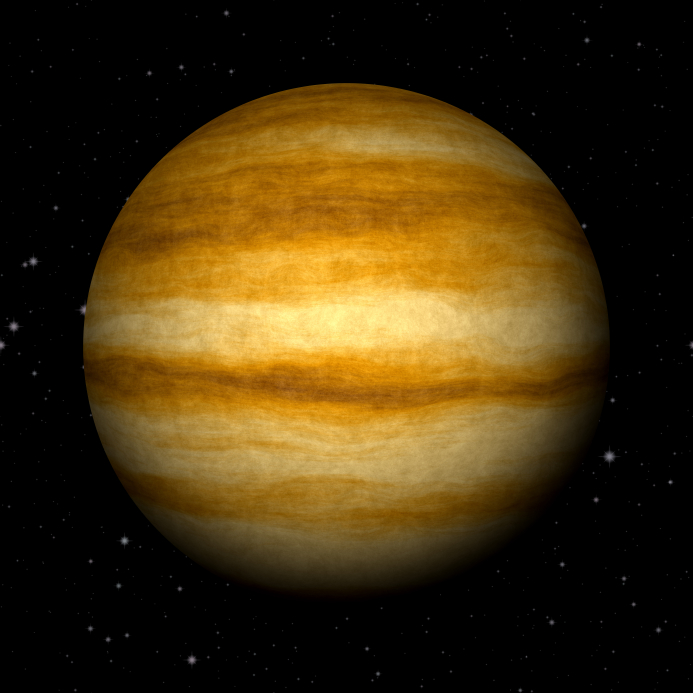

1. Solid Core

Scientists from all over the world keep arguing about the nature of the gigantic planet’s core. Some of them believe it is solid; others that gases present in the atmosphere go all the way down.

2. Sea of Liquid Metallic Hydrogen

Does this exist? Many people believe so, as it will explain Jupiter’s massive magnetic field and its spectacular auroras.

3. The Great Red Spot

This is giant storm that has been alive for hundreds of years. It works like a hurricane but, as far as we know, these need to feed on the liquid that comes from an ocean – and the existence of such thing seems unlikely in Jupiter’s landscape, which is exclusively formed by gas.

Here at European Springs Ireland we believe in the power of technology – starting with the smallest elements, such as springs – to change everyone’s life. Looking for the perfect spring for your project? Don’t hesitate in contacting our expert team today and we’ll be delighted to help.