As premium Irish spring manufacturers and major players in the ever-changing manufacturing industry, we are always looking into the future to try and accurately predict advancements to stay ahead of the competition. Our proactive attitudes are even more relevant when considering the economic and international challenges that our sector has been exposed to in recent years, such as Russia’s war in Ukraine and the changes in government environmental policy.

We believe that despite challenges, Irish manufacturing will overcome and even grow with a bright future ahead of us. Today, we are here to explain the reasoning for our faith in our industry and share a few examples of the bright future ahead for us and our clients.

The State of Irish Manufacturing in 2024

It has been a turbulent 12 months for our nation’s manufacturing industry, as a shift started to occur where the modernised focus was replaced with the reemergence of the traditional manufacturing sector. Data from the Central Statistics Office revealed a fall-off in the highly globalised modern sector that included computers, pharmaceuticals, and chemicals whilst seeing a rise in demand for more traditional industrial areas, such as mining, engineering, and spring manufacturing, as well as general mechanical-based manufacturing.

Over the past 12 months, our industrial sectors have experienced a period of contraction, but it hasn’t been uniform, as some areas fell while others succeeded. In fact, this year, while the modern areas declined by 14.4%, the traditional industrial areas actually grew by 12%.

The lowest point was in April when the PMI (AIB S&P Global Manufacturing Purchasing Managers’ Index) recorded that Ireland fell to 47.6, significantly lower than the 49.6 and 52.2 in the previous two months. This was also the fourth time that the nation’s manufacturing industry has fallen below 50 in the past six months. There have been several explanations posited for these results, including oversaturated markets and overstocked customers, which have led to a fall in new orders.

Despite these challenges to overcome, European Springs IE was amongst a large majority that believed these were temporary setbacks that could be managed. Before the 12-month period was concluded, our faith was indeed rewarded.

In June, a significant increase in output orders was recorded, and the PMI displayed a return to just under 50 (49.8 to be exact). This means we just need to keep being innovative with our business practices, creating new bold strategies to get our country above the all-important 50 mark and back into a steady rate of growth that we are known for worldwide.

The Resilience of the Irish Manufacturing Industry

As spring manufacturers, we need to adapt and pivot when the world changes, as we have all felt the impact of that this decade. We proved incredibly resilient, and despite the many challenges, we have not only maintained our position as a leading manufacturer of compression springs in the region but also grown by adding new staff and equipment to our facility.

Future Predictions for Irish Manufacturing

Despite the past setbacks, we believe the future of manufacturing is bright. To explore why, we have handpicked some stand-out industry advancements that we believe will propel Irish manufacturing and assist with positive change.

Accelerated Digital Transformations

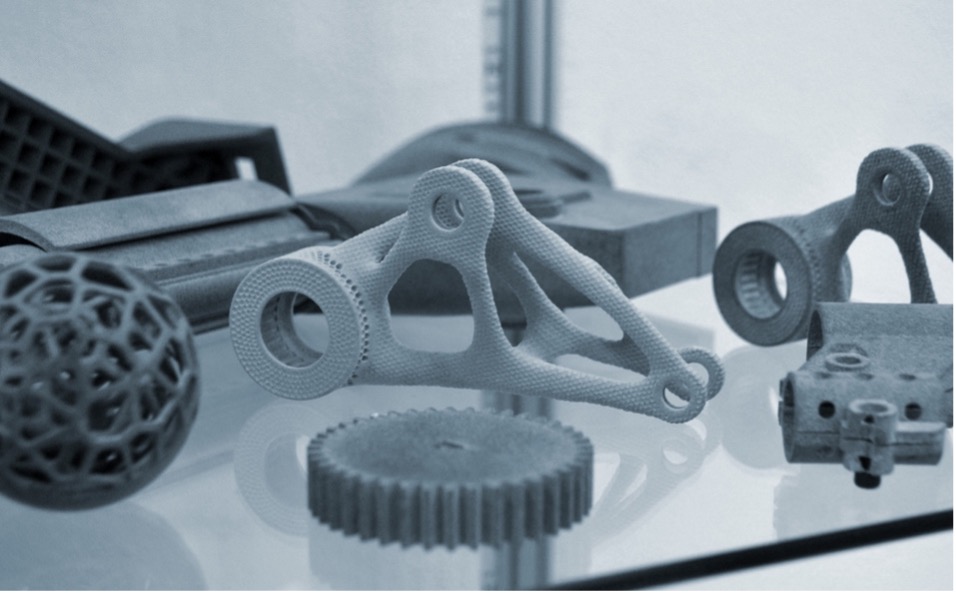

Like every other industry, digital transformations are plentiful within manufacturing. We have already seen a variety of digital advancements in the sector, such as increased automation, IoT, and other innovations to provide upskilling opportunities for staff and remove them from tedious, repetitive actions. This goes hand in hand with technology such as AI, robotics, and virtual reality in engineering, which has also increased in recent years.

Understandably, we believe that these digital transformations will only improve and become much more advanced as time goes on. Complexity will only increase, allowing manufacturing businesses to put many of their systems into technology’s hands and providing business owners with the freedom to work on other areas of their companies.

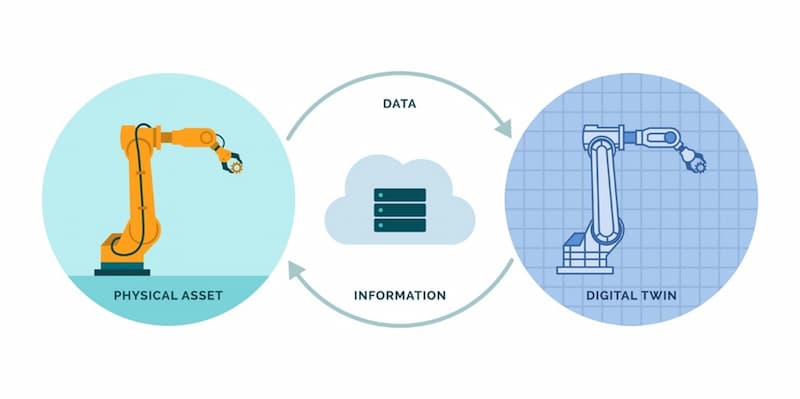

Digital Twin Software

An excellent example of the acceleration of digital transformations is digital twin software. This technology gives users a virtual simulation of a physical asset, which digitally represents its performance. For example, as spring clip manufacturers, we could use digital twin software to mimic a clip and look at ways we can improve its performance and optimise its use in order to provide our customers with the best possible product.

Whilst this isn’t widely used in manufacturing now, we believe it will become a staple in the not-too-distant future. This is because it can save a lot of time, the use of physical products, and space in factories that would have been used for physical testing.

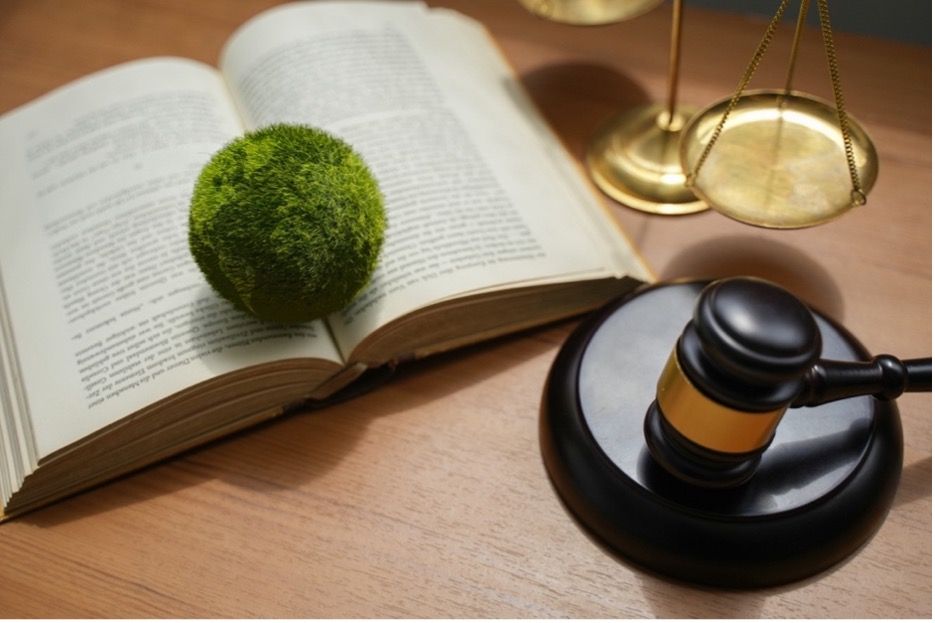

Green Manufacturing Initiatives

As industries worldwide make changes in line with their plans to achieve carbon-neutral status, we believe the manufacturing industry will take significant strides with lean initiative. This means reducing waste during the manufacturing process as well as simultaneously boosting productivity, which is achieved in several ways, for example:

- Efficiently managing your inventory. Managing inventory well means planning ahead, so not ordering too many items which will go to waste if you cannot sell them.

- Investing in sustainable sources. These include choosing recyclable materials such as stainless steel, which is highly recyclable but can also include sourcing materials that are more local to avoid the carbon cost of long-distance transport.

- Reducing packing materials. Whether this means decreasing the size of boxes, removing a layer of plastic, or reducing in another way, less packing is great for the environment and the workplace’s productivity.

- Setting waste management goals. Lean initiatives are much more likely to succeed if they are planned out. For example, setting waste management goals may involve creating a recycling plan that employees can refer to and that will act as a constant reminder.

Reliable Irish Spring Manufacturing: European Springs IE

Of course, the Irish manufacturing industry is just a small factor in the global sector, but we believe these changes will be seen all over the world. As spring and wireform manufacturers, we’re always at the forefront of these big industry advancements to maintain our leading status across this competitive field and compensate for changes easily.

Contact us to discuss your next project’s spring or wireform requirements and discover how we will help you achieve your goals within your deadlines.

Driving Innovation and Product Development

Driving Innovation and Product Development In home construction, extreme precision and overall safety are paramount and non-negotiable. In recent years, sustainability has become another key factor to consider when planning to design and build residential structures. The objective is to achieve results that not only maximise efficiency with minimal environmental impact but are also long-lasting. It is here that pressings are essential components in modern home construction, serving multifaceted roles for durability and strength.

In home construction, extreme precision and overall safety are paramount and non-negotiable. In recent years, sustainability has become another key factor to consider when planning to design and build residential structures. The objective is to achieve results that not only maximise efficiency with minimal environmental impact but are also long-lasting. It is here that pressings are essential components in modern home construction, serving multifaceted roles for durability and strength.