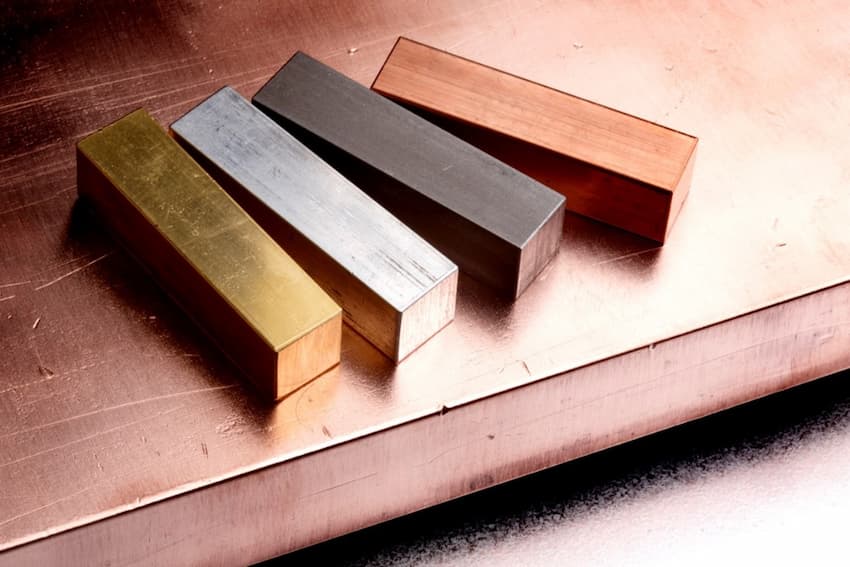

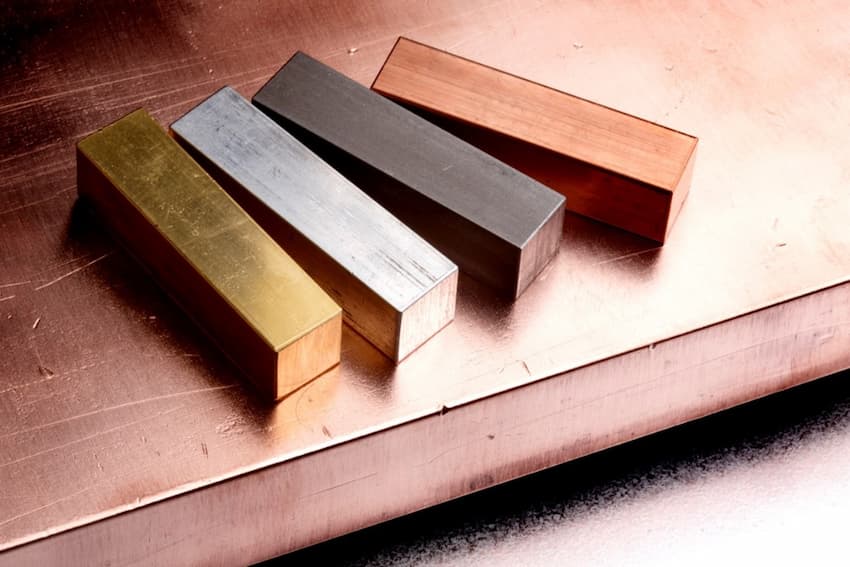

Materials Matter: The Best Options for Springs and Pressings

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process

Home › News & Updates › Page 3

The manufacturing process behind springs and pressings is certainly complex and fascinating. The material choice is central to this process

At European Springs IE, we acknowledge the importance of keeping your finger on the pulse of all recent developments in

Starting a manufacturing apprenticeship is an exciting endeavour, but nerves are to be anticipated, just like starting a full-time job

The Irish manufacturing sector has undergone a remarkable transformation in recent years, driven by advancements in technology and digitalisation. With

As a leading provider of springs and pressings solutions, European Springs Ireland is committed to staying at the forefront of

If you’re considering a career in manufacturing, it’s important to understand that you are always welcome and sure to find

Here at European Springs Ireland, we get the opportunity to work with a wide scope of industries, manufacturing and producing

Deciding your future in your teen years is a daunting experience. You may feel pushed into a corner by peers,

A steady supply chain is vital to any manufacturer’s daily operations. Consequently, new supply chain options have been created to

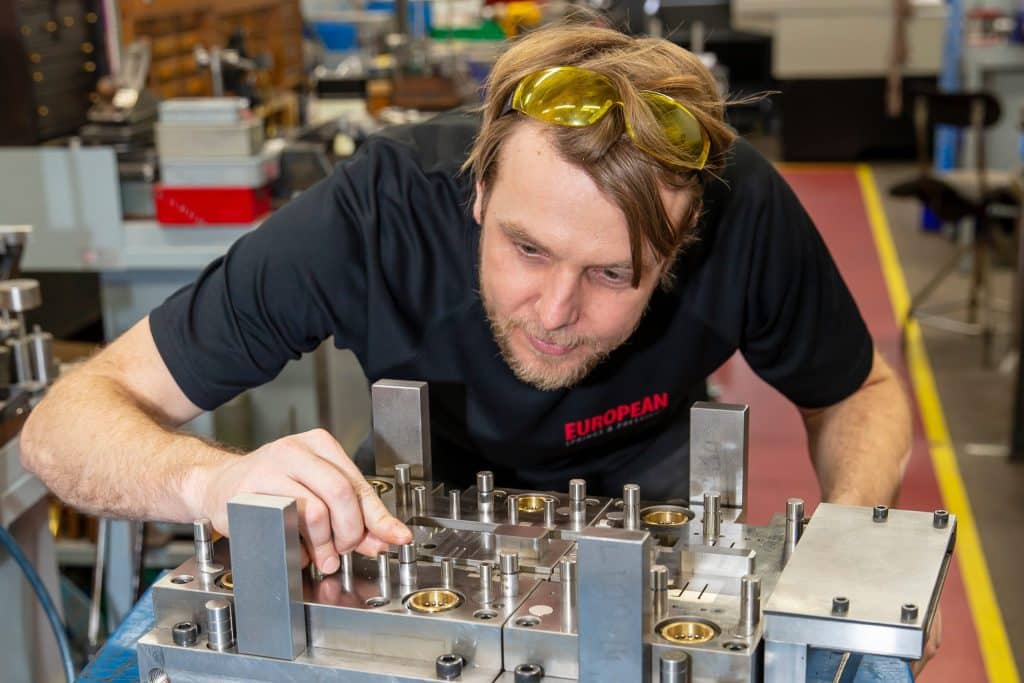

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital