How Tech Can Mould The Future Of Manufacturing

Technology continues to advance at a rapid pace and to create exciting opportunities for those working in manufacturing and its many sectors. As spring manufacturers, we understand just how important it is to keep on top of trends that can impact the industry – and to be aware of how technology will change it!

In this article, we’re taking a look at how technological developments are set to impact the face of manufacturing in the future.

5G Widespread Rollout

2020 will see a rollout of 5G on a larger scale, including in the manufacturing industry. 5G offers faster speeds, better coverage and more stable connections – you can have more devices connected at the same while maintaining the quality of the internet. This will help manufacturers around the world, mainly for smart manufacturing.

This fifth-generation connectivity can also facilitate industrial automation, as well as augmented reality and IoT. 5G is crucial for the digital transformation that the industry is going through. Of course, there are also some challenges associated with this rollout; some people are worried about cybersecurity and the age of the technology.

It’s estimated that there will be more machines connected by 5G than humans by the end of 2020. By improving communication between devices, facilities will see a boost in productivity and improve their capacity to meet more complex customer demands.

Early adoption may be slow, but we believe 5G will eventually become indispensable in manufacturing.

AI Investment

Many sectors make up the manufacturing industry, such as aerospace, and it can be difficult to implement processes and changes – however, with Artificial Intelligence and smarter technologies, you have the opportunity to gain a competitive edge and improve the efficiency of your facilities.

According to IFS, 40% of manufacturers intend to implement AI for inventory planning and logistics, while 36% plan to implement AI in production scheduling and customer relationship management. 60% of all respondents say they want to boost productivity with these investments.

Automation is key in manufacturing. Together with AI, you can better distribute your resources and ensure that your workers are safe from repetitive or dangerous tasks, since these can be performed by machines.

Better Cybersecurity

As technology develops, cybersecurity becomes more important – including in manufacturing. With more connected devices and an increase in automation, vulnerability to cybercrime is also a possibility. Business owners need to understand that, while technology brings with it a wealth of benefits (and the manufacturing of today wouldn’t be the same without it), there are also potential risks to keep in mind.

Blockchain is a way to ensure the cybersecurity of your data, and we believe this technology will be more widely used in 2020. Blockchain is already being used by more and more businesses, so it won’t come as a surprise that the manufacturing industry will also adopt it.

From data decentralisation to secure user ID, blockchain can protect supply chains as well and offer verifiable information about any product.

Increased Focus on Wearables

Wearables don’t have to invoke a futuristic image. In fact, wearable technology is already in use, we just expect to see more of it in 2020. The main focus is on handhelds at the moment but being able to access information from a smartwatch, headset or other types of wearable tech may improve productivity and efficiency – and will ensure that the manufacturing process is even more unobtrusive.

A wearable piece of technology may be able to detect when a worker is experiencing fatigue, for example, which can help to boost employees’ wellbeing as well.

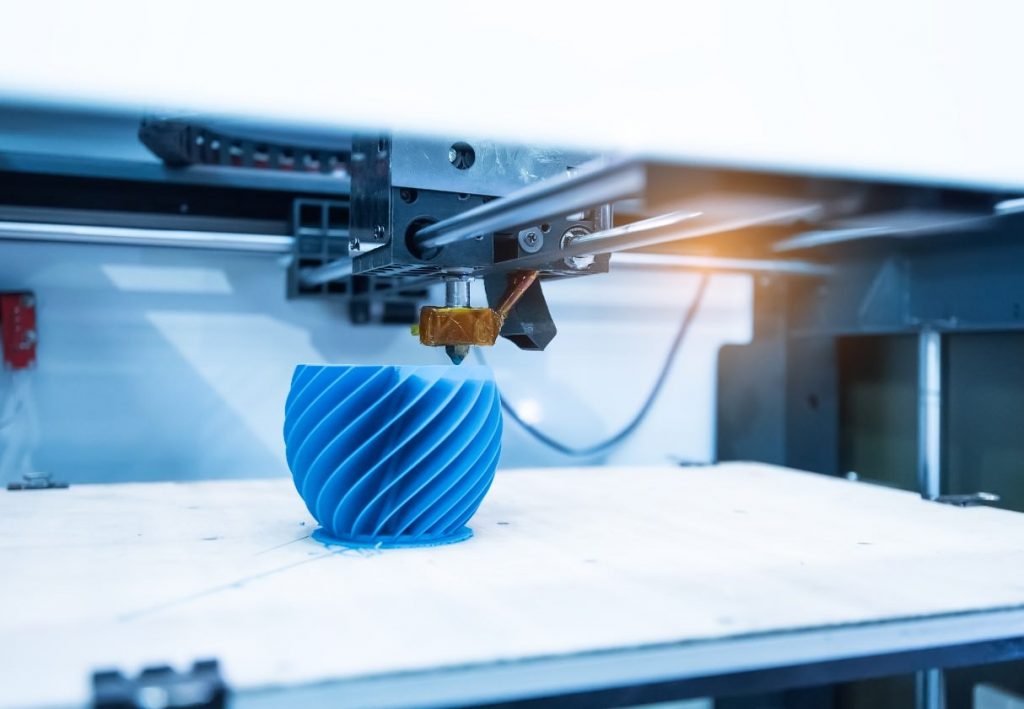

Incorporating 3D Printing

Another technology that is set to change manufacturing is 3D printing (and additive manufacturing in general). It’s estimated that the global 3D printing market will be worth around £15 billion by 2025. The ability to design increasingly complex products and to create objects from innovative materials is key for manufacturing innovation. This will lead to better customisation and, therefore, to better customer experience.

Another benefit of incorporating 3D printing in manufacturing processes is that it reduces waste. Plastic can be recycled and there is no excess of material. This allows manufacturers to cut costs and to reduce their carbon footprint at the same time.

3D printing can also be applied in a variety of industries, from medical devices to children’s toys and aircraft parts.

More Investment in the Internet of Things

We’re previously looked at how the Internet of Things can help the manufacturing industry and with good reason. IoT is transforming manufacturing and will continue to do so for many years to come. More companies and devices are becoming connected and, according to the PwC’s Internet of Things Survey 2019, a staggering 93% of manufacturers believe that the benefits of IoT far exceed its risks – and 68% intend to increase their investment in IoT in the next couple of years.

The Internet of Things can have many different applications, although it’s more popular in logistics, in the supply chain, in predictive maintenance and in the employee and customer experience.

At European Springs Ireland, we like to stay on top of the latest news and technological developments. After all, we aim to continuously improve our products and services and ensure that all our clients receive the best experience. We’re looking forward to seeing how manufacturing will develop – going by how tech is already changing it, we’re expecting a bright future.

If you’re looking for a spring manufacturer that can help you meet the demands of your project, contact us and our friendly team will be in touch.