Sustainability in the Automotive Industry and Why It’s Important

With the automotive industry gaining a reputation for producing harmful greenhouse gasses over the past few decades, leaders within the sector realised that something had to change. Over the past 5 years, a whole host of changes have been made to ensure the impact the industry is having on the environment is minimised, and this has been a genuine success.

In this article, we take a look at the changes that have been made to prolong sustainability in the automotive industry and how they are set to shape the future of car production, as well as how it will affect the end user for years to come.

Green Production – An Important Factor for Sustainability in the Automotive Industry

In years gone by, the automotive production industry had been heavily criticised for their lack of focus on environmentally friendly materials and building techniques. However, in the last few years the industry has seen a shift in thinking and many car manufacturers are incorporating far more recyclable materials into their vehicles.

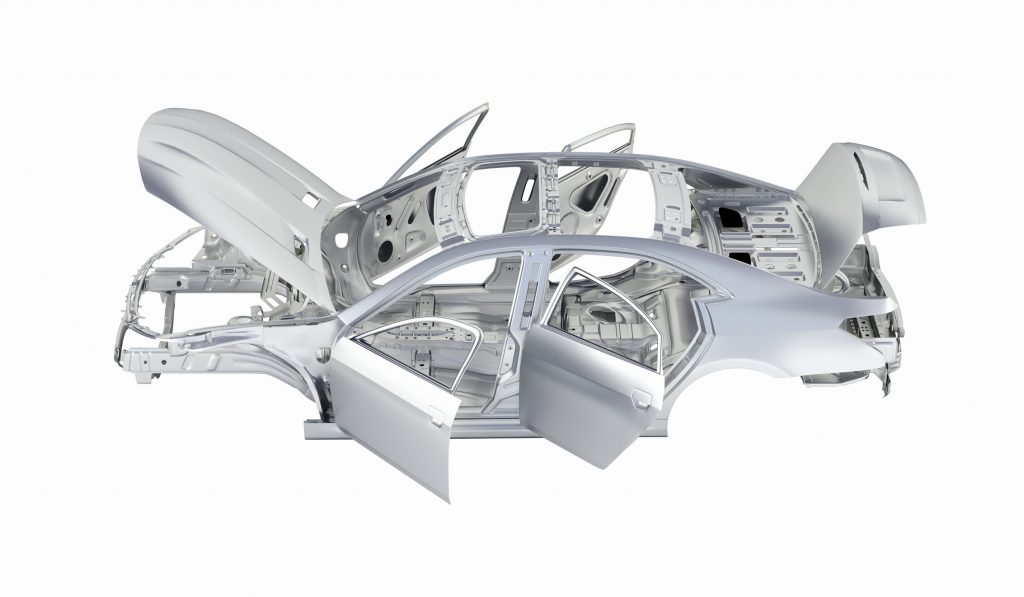

We have started to see aluminium being used in car production far more frequently, which is certainly a step in the right direction due to the material being extremely lightweight and malleable. The use of aluminium as a key component in car manufacturing is a master stroke, as it can be used to manufacture any car and contributes to a significantly lower fuel usage thanks to its lightweight properties.

Another benefit of aluminium being used in car production is just how easily the material is recycled. When cars come to the end of their life cycle, the material can be stripped and reused with ease.

Electric Cars’ Contribution to Sustainability in the Automotive Industry

Electric cars have most certainly been surging into prominence over the past few years. The UK have seen sales of electric cars rise by over 11% in 2018 compared to 2017, which led to the market share of electric vehicles increasing from 1.5% a year ago to 2% this year. Whilst the electric car revolution hasn’t fully hit the UK just yet, it’s clear to see many people are making the switch from petrol and diesel to electric-powered cars.

It may appear that the UK isn’t likely to let go of their petrol- and diesel-powered cars without a fight, but it certainly is achievable within the next decade. Take Norway for example, almost half of the vehicles on their roads (48%) are now running almost exclusively off the nation’s hydro power resource.

Whilst electric cars are still in their infancy, there’s no doubt that this type of sustainable transport is here to stay. Over the coming years, we expect to see electric powered cars taking a larger share of the market, before eventually overtaking the sales of petrol- and diesel-powered cars.

Long-Haul Lorries Heading Towards Electric Power

It’s not just cars that are on the road to being powered by electricity; lorries look set to be heading down the same route too, with long-haul freight lorries being the main contributors to carbon emissions across the globe. Whilst there is a long way to go before electric-powered trucks hit our roads in full force, steps are being made to incorporate the technology into the next generation of fleet vehicles.

Both Tesla and Nikola are leading the way in hydrogen-electric lorry technology and the former are confident they will have their trucks on the road before the end of 2020. The Tesla Semi, an electric-powered lorry capable of carrying up to 36 tonnes over distances of 300 miles, has already attracted over 500 orders from globally renowned companies such as Pepsi, UPS and DHL, among others.

With this technology looking set to revolutionise the fleet industry in the coming decades, it comes as no surprise that huge brands are backing the environmentally friendly alternative to traditional automotive fuels. Along with creating virtually no carbon emissions, electric-powered lorries will be providing massive savings thanks to lower fuel costs and a longer engine lifespan, which will lead to less vehicle maintenance being required.

As spring manufacturers, we are keen to keep our finger on the pulse of the very latest in environmentally friendly practices across all manufacturing sectors. We pride ourselves on keeping up-to-date with the very latest processes to ensure we are working in the most sustainable and environmentally friendly way possible.