Tuning In: Harnessing the Power of Radio

The engineering and manufacturing sectors are hugely innovative fields, constantly evolving in line with the development of new technologies.

Interestingly, according to a recent article from The Engineer, we may be on the brink of another such ground-breaking innovation, thanks to the development of an emerging technology known a Radio Frequency Identification (RFID), which has the potential to transform the production of bespoke products.

At one time, bespoke products were considered a luxury and the standardisation of products on assembly lines was very much the done thing. In the immortal words of the motoring giant Henry Ford: ‘You can get in it any colour, as long as it is black.’

However, in more recent years, thanks to the development of ever-more sophisticated factory robots and software programmes, production lines are more flexible than ever before. Customers, too, increasingly demand more bespoke products and the race is very much on for manufacturers to find ways of producing such products, whilst also keeping production costs low, which is where this pioneering technology comes in.

What is it Radio Frequency Identification?

RFID technology has existed since the 1940’s and was originally used for the identification of military aircraft. In later years, the technology was used extensively for inventory control applications. However, despite its relatively long history, the technology is still very much in its formative stages.

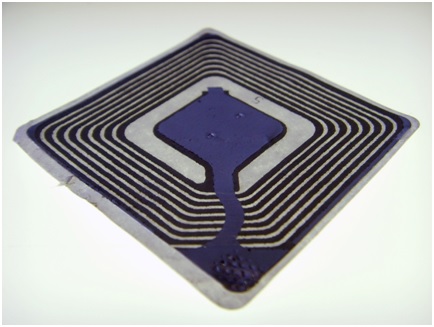

Simply put, RFID is a type of tagging technology which utilises radio waves to automatically keep track of products. RFID systems typically consist of three crucial elements: a tag which is essentially a data storage medium that reveals its information when prompted to do so; a reader which energise the tag by emitting a short range radio signal, prompting it to revel its stored information; and a control system. The reader passes on the information it receives from the tag to the control system, which can then act upon this data.

Industries such as the automotive sector are already employing the technology. For example, RFID has been used on car assembly lines to verify the unique ID of a vehicle’s body body. Once the identity of the body has been verified, this information is then fed back to a control system that instructs the automated spray booth to paint the car with the appropriate colour.

The pharmaceutical and aerospace industries are also adopting the technology to improve tracking and traceability. This is particularly important for companies within the pharmaceutical industry, who are required to trace products through the manufacturing process and keep detailed records, in order to comply with legislative requirements.

According to the article, with further development, the potential of this technology is huge and some experts have even predicted that the cost benefits of technologies such as RFDI could even usher in a new industrial revolution in the next decade or two, helping to make the creation of bespoke products on large production lines commonplace.

Here at European Springs, we’re passionate about engineering and like to keep up-to-date with all the latest innovations from this exciting field. We’re a leading spring manufacturer and many of our high-quality spring products are utilised for a broad range of applications within the engineering field. For more information please don’t hesitate to contact us today, by giving us a call on 0044 7889 171 165 and a member of our expert team will be happy to help you with your enquiries.