Types of Springs Used in the Medical Sector

Springs serve a wide variety of purposes across many industries, from aerospace to electronics. One sector where springs play a particularly vital role is healthcare. From hospital beds to life-saving medical devices, the applications of springs in the medical industry are vast and essential.

At European Springs and Pressings Ireland, we specialise in manufacturing high-quality springs designed to ensure safe, reliable, and efficient performance.

In this blog, we’ll explore how different types of springs, including compression springs, gas springs, and torsion springs, support critical medical applications. Keep reading to discover how our products help maintain the highest standards of reliability in healthcare.

Compression Springs

Compression springs are among the most commonly used springs in the medical sector, thanks to their versatility and reliability. These springs feature a helical design, enabling them to store and release mechanical energy through compression and decompression. Their simple yet effective function makes them indispensable in various healthcare applications.

One everyday example of compression springs in medicine is their use in inhalers. Here, the spring applies force to move medication from the canister into the mouthpiece, where it can be inhaled by the patient.

In surgical instruments like clamps and scissors, compression springs help maintain consistent pressure, ensuring secure tissue handling during procedures. The use of high-quality, durable springs is crucial in these tools, as precision is essential for successful surgical outcomes.

Compression springs are also integral to ventilators, where they help regulate airflow by controlling the pressure of delivered air – a critical function that supports patient breathing. Additionally, these springs are found in medical syringes, particularly within the plunger mechanism, allowing for the controlled and accurate administration of medication.

From life-saving devices to everyday medical tools, compression springs serve as a reliable and versatile component, contributing significantly to the efficiency and safety of healthcare equipment.

Gas Springs

Gas springs, otherwise known as gas struts, are springs that incorporate compressed gas into their functionality. They have a variety of applications, from vehicles to adjustable furniture, and are designed to lift, lower, and control the movement of heavy loads.

Within the healthcare industry, gas springs are used in hospital and physiotherapy beds, enabling height adjustment and back or leg elevation, helping to comfort the patient and make treatment easier for medical workers. The same functionality applies to things like drug cabinets and mobile workstations, assisting with height adjustment, angle readjustment and the control of lid opening and closing.

Gas springs are commonly found in areas of lighting or mounting within a hospital. For instance, the lighting arms that overlook patients and staff in an operating room rely on gas springs, as well as X-ray or live TV screens. This goes for outside the hospital, too, as similar kinds of lighting arms are found in the rooms of dentists and opticians. Gas springs allow these to be moved easily, ensuring that they are positioned in the ideal spot for both the patient and practitioner.

Torsion Springs

Torsion springs work by applying a twisting force rather than a compressive force. When the spring is twisted, it stores energy that is released when the spring reverts to its original position. They are also a common and versatile spring type, making them suited to a vast range of applications. For instance, medical mobilisation devices and hospital beds utilise torsion springs. They assist in smoothly raising or lowering sections of a hospital bed with minimal effort, as well as allowing the beds to lock into place once the desired position is achieved.

Torsion springs can also be found in diagnostic equipment, such as blood analysers, where they help to achieve the precise movement and handling of blood samples. They are also playing a vital role in the evolving sphere of surgical robotics and prosthetics, helping to facilitate movement in a controlled yet natural way. The spring’s torque function is able to replicate the natural bending and straightening movement of a human joint, aiding the creation of more realistic and functional prosthetic limbs.

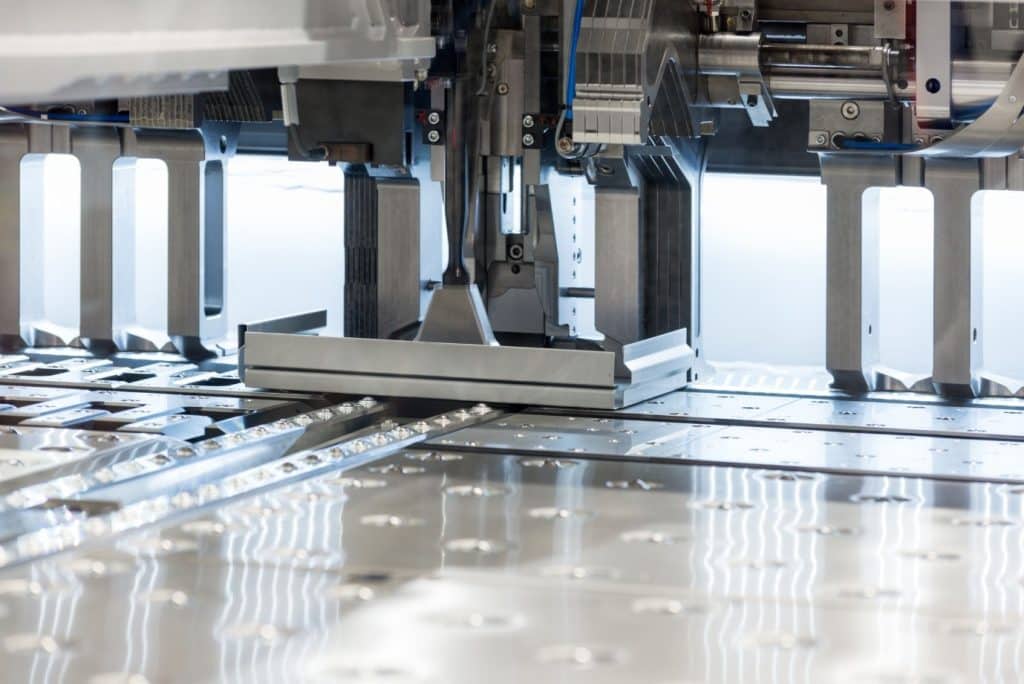

Metal Stampings

In addition to springs, pressings and stampings have an abundance of uses in the medical sector. Metal stampings are created using a process of cutting or shaping metal sheets and can create a variety of components, from flat parts to three-dimensional shapes. When creating stampings and pressings for the medical industry, using sterile, high-quality materials is imperative for maintaining hygiene and easy cleaning. Materials like stainless steel are particularly adapted to this purpose, as they are resistant to corrosion and are a sterile type of metal.

Many common medical parts, including surgical instruments, medical device enclosures, imaging equipment and temperature probes, are made up at least in part from medical pressings and stampings. When it comes to pressings and stampings, we are equipped to handle a range of custom requests, dealing with materials in thicknesses anywhere between 0.05mm and 4mm. We are also able to construct your springs and pressings from a selection of materials, including stainless steel, ensuring that your products are surgical grade.

When it comes to the medical industry, springs and pressings must be constructed of the highest quality and materials, as the consequences of their failure are drastic. That’s why it must be a priority to select a spring manufacturer that has years of experience and high standards, like us here at European Springs and Pressings Ireland. If you would like to discuss the production of a custom product for the medical industry, please don’t hesitate to get in touch.